How To Install Titanium Intake Exhaust Studs

Posted by Matthew Marks on 2nd Aug 2024

Today, we will cover how to install titanium intake exhaust studs, the tools you need, and the best methods.

Titanium is a great, popular replacement for OEM intake or exhaust studs. It is far more corrosion-resistant than steel, up to 45% lighter, and incredibly strong.

Another huge advantage is when using a thermal intake gasket or aftermarket intake or exhaust manifolds, where the flanges are much thicker than stock. Sometimes, the OEM studs are not long enough, so an aftermarket replacement stud that is longer can sometimes help.

We have used titanium studs in our builds for the last few years, and even today, in our turbo Honda B-Series, they still look as fresh as the day we installed them!

We have just released a brand new installation video for this installation. If you would prefer to watch it, click the video below.

Please subscribe to our YouTube channel, as many more installation guides are coming up!

Let's move on to the tools you will need for the job.

Tools You Will Need For Installation

You will need a few tools before starting the job, so make sure to gather all of these before you start the installation. The spanners or sockets will mainly depend on how much room you have to play with, as sometimes spanners are much easier to get in small gaps than sockets.

The torque wrench is optional, but we always recommend torquing the nuts after installation to the factory specifications.

Tools List:

- Titanium intake exhaust studs

- 3mm Allen key or socket

- A ratchet

- 12mm spanners and sockets

- Anti-seize grease or compound

Optional tools and parts:

- Torque wrench

- New intake or exhaust gasket

- Gloves

- WD40

Now that you have all the necessary tools let's install the titanium intake exhaust studs.

Installation Steps For Titanium Intake Or Exhaust Studs

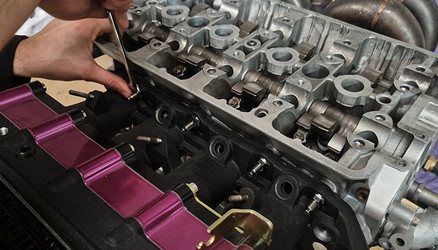

Follow our easy step-by-step guide below to get up and running with your titanium intake exhaust studs as soon as possible. For this guide, we will be using our shop Honda B-Series engine, which we have here for development, but if you are using any other engine, double-check the pitch and thread before you start.

As a side note, we also offer these in m10 for applications such as the Honda K-Series exhaust or any other engine using this thread.

1. Remove The Intake Or Exhaust Manifold

First, you will want to remove the old intake or exhaust manifold. Do this by removing anything attached to it, such as vacuum lines, wiring, or anything else that prevents the manifold from being removed from the engine.

Make sure you either the label or remember where everything goes when you install this back onto the engine later.

Once you have removed everything from the manifold, loosen the nuts or bolts holding it to the cylinder head. Once these are all removed, you should be able to remove the manifold from the engine and put it aside for later use.

If your old gasket is damaged or worn, we always recommend replacing it. OEM Honda intake manifold gaskets will likely break off in pieces, so you will have to replace them regardless. Clean the cylinder head and install the new gasket before installing the manifold.

2. Remove The Old Intake Or Exhaust Studs

You should be left with only studs sticking out of the cylinder head, but these must be removed to proceed to the next step. The best way to do this would be to use a stud extractor, which you can pick up relatively cheaply at any hardware store or online.

We normally use the method of tightening two nuts together to remove the stud from the head.

Start by threading both nuts onto the stud you want to remove, facing opposite directions so the flat faces are touching. Get it to a good enough point where you will have enough leverage to remove the stud and tighten them together as much as possible.

Now, start undoing the outward-facing nut sharply. This should be enough to break the seal of the stud, and it will start to become loose. You can remove the stud until it is loose enough to thread out by hand, then undo the two locked nuts.

If you are struggling to remove the stud at this point, the nuts are likely not tight enough to break the seal of the stud into the block. Soak them in WD40, retighten the nuts and repeat the process until the stud starts moving.

You can repeat this step for every stud you need to remove and move on to the next step.

3. Install The New Titanium Intake Exhaust Studs

Start by using a small amount of your anti-seize compound on the part of the stud that will sit in the cylinder head and threading it in by hand.

We always recommend using an anti-seize compound or grease when installing titanium into aluminium cylinder heads to reduce the chance of galling over time.

When you cannot go any further, use the 3mm hex tip socket or Allen key to thread the titanium stud the rest of the way.

Our titanium intake exhaust studs have a shoulder midway down the stud, so you cannot tighten them too far into the head. Once this has bottomed out, you are all done and can repeat the step for the rest of the studs.

Torque the titanium studs to a maximum of 30Nm or 22Lb/ft, and you start installing the intake or exhaust manifold.

Slide the gasket on first, then install the exhaust or intake manifold. Thread on all of the m8 titanium nuts by hand, then tighten them using the 12mm socket, spanner, or a combination of both.

4. Torque To The Factory Specifications

Last, you will want to torque all of the nuts to the factory specification of your engine and then reinstall everything on the exhaust or intake manifold you removed earlier.

Once you are all done, test the car for leaks by running the engine and return to re-torque the nuts after a few heat cycles. This is important as the metal expands and contracts over time, so you will always want to recheck the torque to ensure they have not loosened over time.

You are done with your installation, and you should have some fresh, new, shiny titanium hardware to show off!

Products Used In This Installation Guide

We currently sell some of the products used in this guide, so if you are interested, need any extra, or have not already purchased them, check them out using the link below.

If you are considering buying anything from this guide, then please use the specific blog reader discount code:

BLOG5

For a discount on your entire order!

This is massively helpful for us and will help us write more installation guides like this one.

[dib_prod_913]

Frequently Asked Questions

Q. Is titanium as strong as steel?

A. This would depend on which grade of titanium you are using. Our titanium grade 5 is equivalent to around an 8.8 steel bolt, so it would not be able to be used for something such as a lower control arm bolt as the tensile strength is not high enough, but it is a perfect replacement for something such as an intake or exhaust stud, or to replace any 8.8 grade bolt on the engine or engine bay.

Q. Why should I use an anti-seize compound?

A. When using titanium intake exhaust studs or bolts in an aluminium cylinder head, you can often have a galling effect, where the metals bond together, especially when considerable force keeps them together.

The anti-seize compound will help to counteract this, so we would always recommend using them to reduce the chance of this happening.

This is also beneficial after removing the studs for a long time, as it will massively reduce the chance of the titanium stud getting stuck in the cylinder head.

Conclusion

So that's it—our titanium intake exhaust studs installation guide. Hopefully, you are now confident in your ability to install yourself and can give it a go. We mentioned Honda a few times in this guide, but our studs will also fit multiple other cars.

We had a customer phone up a few weeks back with a Porsche Boxster 986, and these studs were the correct thread and pitch for his application!

If you are interested in any of our related installation guides or other articles, then head to some of these links here:

- How to install exhaust wrap

- How to install heat reflective tape

- How to install AN fittings to braided rubber hose

- How to choose a K-Series map sensor

Did you learn anything new? Or if you'd like to share your current projects, please comment below!