What Is A Swirl Pot And How Do They Work?

Posted by Kym Allen on 1st Aug 2024

If you have ever wondered what a swirl pot or surge tank is, this is the guide for you! We first need to understand the benefits of using a swirl pot and the best ways to install one.

We have now filmed a full video on how to install a swirl pot, so if you are interested watch the video below. We go over the different types of systems and how to plumb it in.

What Is Fuel Surge (Starvation)?

Firstly, we need to understand a fuel surge and its adverse effects on your car.

The leading cause of fuel surge or starvation is when a car accelerates, brakes, or corners hard where the fuel can shift in the tank away from the fuel pickup.

The fuel far from the pickup will pull air into the fuel system. When a fuel-injected engine is starved of fuel, even for a limited amount of time, it will, at the very least, slow you down by causing the engine to “splutter”.

However, the worst-case example would be damage to your engine and fuel pump, especially if this happened regularly, like fast cornering on track.

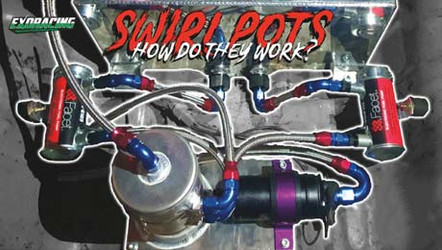

We installed an entire swirl pot system in our turbo civic a few weeks back, so if you need the see the installation visually, watch our video below.

If you drive a standard factory car to work and back abiding by all traffic laws, you would likely never experience this.

However, if you have added forced induction to a vehicle or increased the power excessively, it might be time to invest in your fuel system.

If you are running high-power carburettors, they likely have a big enough float chamber to compensate for fuel surge.

What Is A Swirl Pot / Surge Tank?

A surge tank or commonly known as a swirl pot, is usually a small one or two-litre cylinder located near the fuel tank that

acts as a supporting fuel tank between your main tank and the engine.

The idea behind the name 'swirl pot' is that when the fuel enters the pot, it is forced in at an angle that spins the fuel around the tank, the same way water goes down the bathplug.

Because the fuel is swirling around the tank, it does not matter which direction the car is going or how fast it is doing it; the fuel is constantly being forced around the pot to the bottom, where the main pump will pick up the fuel and send it to the fuel rail.

How does a swirl pot work?

The fuel is taken from the main tank via lifter pumps in a fuel system with a fuel swirl pot. This process will always keep the swirl pot full of fuel.

The main pump draws fuel along the system to the fuel pressure regulator. The regulator then dictates how much fuel goes into the rail and how much is returned.

The swirl pot has a return back into the main tank that keeps the fuel in the pot at the correct level. Without this, the swirl pot could become massively pressurised, resulting in the tank bursting and leaking fuel into the car.

What are the benefits of a swirl pot?

The main benefit of a swirl pot system is ensuring that you never encounter fuel starvation. Suppose you are planning to run a cheaper aluminium fuel cell.

In that case, you are even more likely to face fuel starvation as the more inferior tanks are generally not baffled, and the fuel can move around the tank very quickly.

If you remove the original fuel tank and replace it with a fuel cell and surge tank, you could also save yourself some weight in the process.

Many older fuel tanks are cumbersome and weigh much compared to modern aluminium tanks. Moving the fuel system to the car's boot also may work in your favour for distributing weight around the car.

Many vehicles come out of the factory front heavy; evening this out can help pull some weight back and balance the car.

Is there any reason to not run a swirl pot?

Sometimes, a swirl pot will have the pump inside, but if it does not, you will have to fit an external lifter pump and main pump inside your car. These can be very loud! If you plan on daily driving the car, in-tank pumps may be the way to go.

Safety is also essential when fitting a fuel system inside your car with a fuel cell and swirl pot. Usually, the fuel system is added into the boot, where there is a lot of room to fit everything needed.

However, in the event of being rear-ended, it would be possible for the fuel system to be compromised on impact.

The fuel inside the vehicle is a massive safety risk, and if you plan on doing such an install, it would be wise to add a rear crash bar and a firewall to protect yourself.

Can I Install A Swirl Pot Myself?

Fitting a fuel system is something that you should do with great caution. The physical installation of a fuel cell, swirl pot and pumps is straightforward where mounting holes need to be drilled, then can bolt everything.

The challenges come with getting the new fuel lines made with AN fittings, ensuring no leaks.

The fuel inside the car is hazardous, as you can probably imagine! It would be possible to use a rubber hose with push-on fittings.

However, if you are running these lines through the car, there is a strong chance they will leak fuel vapour in the cabin.

Rubber hose is also delicate and can be easily damaged. It is possible to get a rubber hose with stainless steel braiding around it to protect the line.

The best option would be to go with a Teflon (PTFE) line. With modern fuels having an increasing amount of ethanol in them, the rubber hose would perish with time if using more ethanol than UK pump fuel and need replacing more often.

However, the Teflon line is resistant to ethanol, meaning it can be used with most fuel, even race fuel, plus you do not get any fuel vapour inside the car!

On each fuel line you run, both ends will need a fitting of some type. The safest for this application would be AN fittings.

These are forced over the line and then tightened with AN spanners ensuring a solid seal and no damage to the fitting.

If you have yet to gain experience with this, getting a professional to help prepare the lines is best.

When choosing what swirl pot to go with, you need to consider how much fuel you will need.

You would only need one lifter pump for some applications, which means fewer ports on the swirl port. It is best to choose which pumps are going to be the best for your application.

Choosing the correct fuel pump and lifter pumps is, again, more complicated.

You need to work out how much LPH you need (litres per hour), then match the lifter pumps to the main fuel pump to ensure even fuel delivery.

After all of this has been installed, the wiring still needs to be done.

Wiring for some people can be the most complicated bit of all. Most fuel cells have sender units that tell you how much fuel is in the tank; these can be wired into the old fuel gauge in the car. Each pump must also be wired in, including the correct relays.

If you are interested in building your fuel system, we can supply everything needed and advise choosing the proper hardware for your needs.