7 Engine Bay Heat Myths Debunked

Posted by Matthew Marks on 16th Jan 2026

Today, we are going to be debunking 7 of the most common engine bay heat myths.

Having dealt with heat management for the last eight years, we have encountered some absolutely crazy and wild myths, as well as some that are a bit more believable.

The 7 in the list we are going to cover today are on the more tame scale, which some customers believe to be true, and we are going to show real-world applications.

More importantly, we will delve into why these claims aren't true and present some testing and real-world issues we've encountered with our own customers to settle the matter once and for all.

I’m Matt, owner of Exoracing. Since 2018, I’ve been building and testing performance cars and helping thousands of customers tackle heat issues. From turbo street Civics to full track builds, we’ve seen what actually works to control engine bay heat and what does not.

By the end of this guide, you’ll know how to manage engine bay heat, protect vital components, and improve reliability without expensive parts or specialist tools.

Buckle up because this is going to be a long, in-depth one!

We’ll break down seven common myths and show the real truth behind each one.

This guide is brought to you by Exoracing, UK specialists in heat management and performance parts.

- Coolant temps do not always tell you how hot your engine bay parts are getting.

- Turbo blankets, wraps, tape, and sleeves can cut radiant heat and heat soak.

- We share real-world results and simple upgrades that protect wiring, hoses, and performance.

1. Myth: Turbo blankets will overheat your turbo or catch fire

It’s often said online that wrapping a turbo in a blanket will “cook” the turbocharger or cause it to overheat and fail.

Some even claim that turbo blankets can catch fire. In reality, a properly designed turbo blanket keeps heat in the turbine housing (where it belongs) and reduces the radiant heat soaking the rest of your engine bay.

The turbo’s core is designed to handle extreme heat, and containing that heat actually helps the turbo work more efficiently by keeping exhaust gases hot and fast.

We’ve run high-boost cars with our own Exoracing Turbo Blanket V3 and saw no negative impact on the turbo itself over time, only benefits like cooler intake temps and less heat fatigue on nearby parts.

As a good example here, we have had professional drifter Martin Wonacott use our V3 turbo blanket on his 800-1000bhp Toyota Chaser screaming at the limit at every event for the past 6 years, and the blanket has never caused a fire or a single problem.

This is an extreme example for sure, but it also shows you that at the highest end of motorsport, the drivers opt for turbo blankets as they understand the value in them being able to reduce radiant heat, and would not put their £100,000 plus builds at risk if this myth were actually true.

Quality matters, though, as cheap, flimsy blankets might degrade, but a well-made blanket uses fire-resistant materials (fibreglass, silica, titanium layers, etc.) that can withstand the heat cycles.

We even torture-tested our latest turbo blanket with a direct blowtorch flame; it didn’t ignite or fall apart at all.

The outer layer didn't even discolour, proving that the blanket was insulating so well that its surface stayed cool and did its job.

In normal use, your turbo will never get as hot as a blowtorch flame, so a good blanket has plenty of safety margin.

The only real risk, and the reason this myth exists, is that if the blanket gets contaminated (for example, soaked in oil from a leak), then any insulation could smoulder.

Contamination is the only time a quality turbo blanket can catch fire, and we have seen this happen on the internet before, but this isn't the fault of the blanket itself.

It's like putting lighter fluid on your bonnet and putting a flame to it. It isn't the bonnet that caused the problem; it was the accelerator, which is where we can squash this myth.

I'm going to add our two testing videos aswell here to show you that with a blowtorch on the inside and outside, they just don't catch fire.

The solution is simple: fix any leaks before installing, and check the blanket periodically. In our experience, a clean, correctly fitted turbo blanket is very safe and drastically cuts down under-hood temps without harming your turbo at all.

2. Myth: Exhaust wrap causes rust and cracked manifolds

Another myth on the list is that wrapping your exhaust manifold or downpipe will trap moisture and overheat the metal, leading to rusty or cracked pipes.

We’ve heard the horror stories, but here’s the truth: Exhaust wraps themselves don’t magically destroy exhausts.

In fact, we’ve wrapped ourselves and sold thousands of rolls of our titanium exhaust wrap and have not seen failures on good-quality steel.

The wrap’s job is to hold heat in the exhaust gases and reduce how much radiates into the engine bay. That extra heat can stress subpar metal, for example, a cheap mild-steel manifold might develop hairline cracks if it’s thin and can’t handle the higher internal temperatures.

But a high-grade stainless steel or cast manifold in good condition will be just fine. It’s a matter of material quality, not the wrap itself.

What about moisture and rust?

It’s true that if the exhaust wrap gets soaked and stays wet, it could promote corrosion on plain steel over time.

But in normal operation, the exhaust gets so hot that any moisture burns off quickly. Problems only occur if someone wraps the very tail end of an exhaust (which doesn’t get hot enough to dry out) or if the car is left sitting outside for ages with a drenched wrap.

For engine bay sections, the pipes regularly get to hundreds of degrees, evaporating water on the exhaust wrap before rust can form underneath.

We advise wrapping the hottest parts (header, turbo downpipe) and not bothering with the backbox or far-rear sections.

That way, you get the heat containment where it counts and avoid any constantly wet areas.

When done right, exhaust wrap yields big benefits. When we wrapped our turbo Civic’s manifold and downpipe, we immediately noticed far less heat radiating under the bonnet, and you can actually touch nearby components without burning your hand after a pull, whereas before it was untouchable.

Under bonnet temps drop significantly, which helps intake air stay cooler (more potential power) and protects plastic and wiring from melting.

There’s even a slight performance gain: keeping exhaust gases hotter improves their flow, which can help turbo spool and reduce turbo lag a bit.

In short, a quality wrap installed properly on a quality manifold is a smart move for heat management, not a death sentence for your exhaust.

Just remember to secure it tightly with stainless ties and overlap the wrap consistently for even coverage.

To learn how to correctly install exhaust wrap and learn everything there is to know, watch our video below.

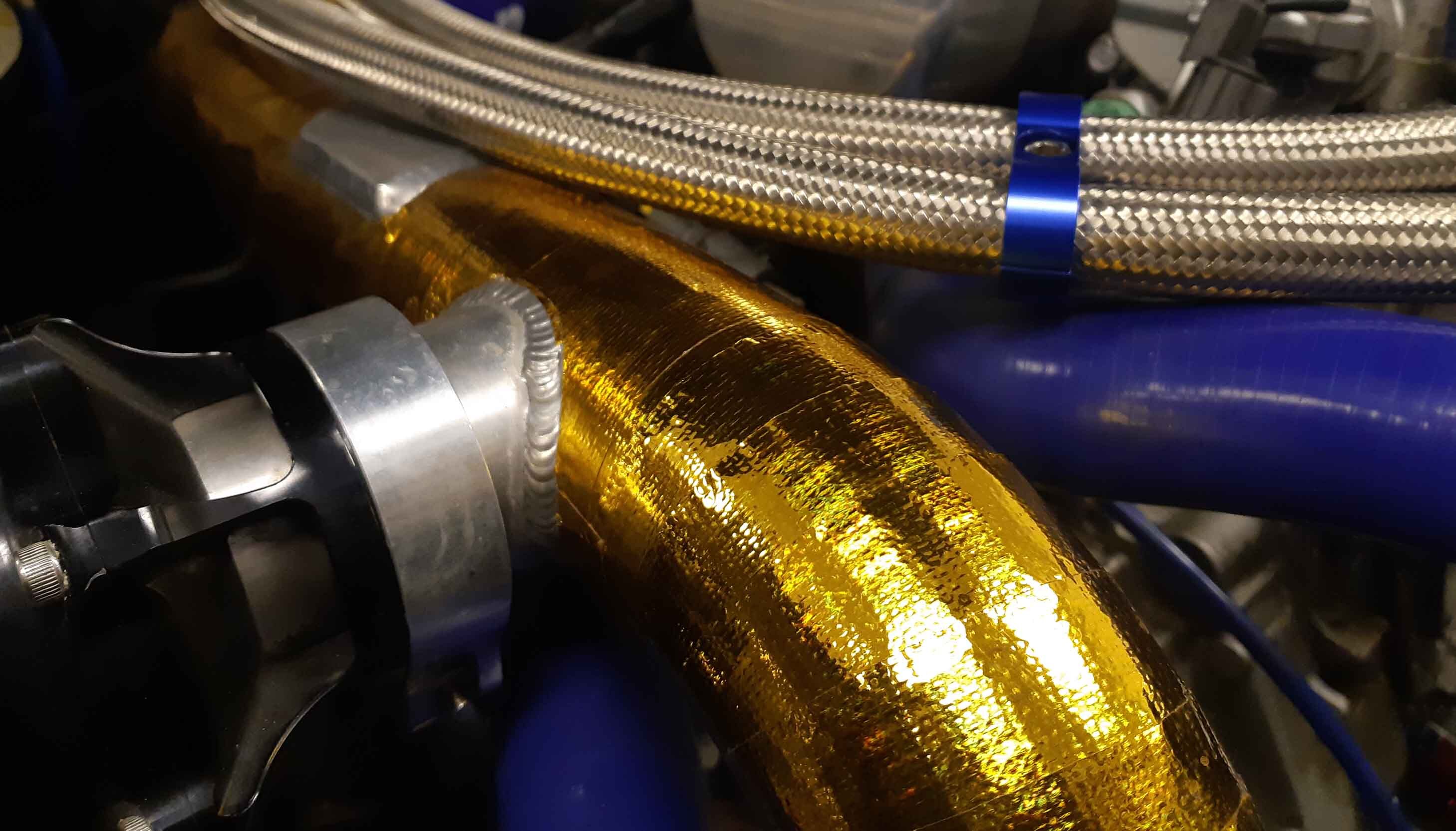

3. Myth: Heat reflective tape is just for looks

You’ve probably seen gold or silver foil wrap under bonnets and on intake pipes and wondered if they actually do anything.

Some sceptics dismiss reflective heat tape as “bling” or a gimmick. The truth is, heat reflective tape and foil can significantly reduce radiant heat transfer when applied correctly.

These heat reflective tapes have an aluminised layer that reflects radiant heat away from whatever they’re applied to. So, if you stick reflective foil on the underside of a plastic airbox, or around a fuel line or wiring harness, it will help shield it from a nearby heat source (like a turbo or exhaust pipe).

No, it’s not going to make things ice-cold, but it absolutely creates a temperature difference that can be the difference between a part surviving or failing.

We’ve used reflective tape in some brutal environments. For example, in one of our customers’ cars, the washer fluid reservoir sat uncomfortably close to the turbo downpipe.

The solution? We wrapped the side of the plastic bottle facing the turbo with our gold reflective tape and paired it with a turbo blanket on the hot side.

The result: despite the turbo glowing inches away, the plastic bottle never melted or got damaged, even after 3 years of abuse!

The video below is the car in question, Scott's 430whp k-swapped Honda Concerto.

The tape reflected a huge chunk of the radiant heat, and what little warmth got through was not enough to deform the plastic. In a sense, reflective tape acts like a mirror for heat, just simple physics.

We now have a guide which might be helpful if you are interested in the different types of heat. Click here to learn about convection, conduction and radiant heat.

Once you learn about all 3 such as reflective tape reducing radiant heat, you can quickly and easily counter it.

Forreal-life wiring and hoses, reflective sleeves or tape can be a lifesaver.

Rather than those components absorbing continuous radiant heat (which over time can make wire insulation brittle or hoses more likely to crack), the reflective layer keeps them running cooler.

We like to use our Exoracing gold & silver velcro heat sleeve on fuel lines, wiring, and hoses in high-HP builds, and it’s an inexpensive safeguard to keep everything working its best long term.

Now, it is true that just slapping gold tape everywhere won’t magically fix a severely overheated engine bay. It’s best used as one layer of defence for specific components.

Think of it this way: turbo blankets and exhaust wraps contain heat at the source, while reflective tape deflects radiant heat away from things you need to keep cool.

In combination, they work wonders. So no, it’s not snake oil; it has a real function. (And hey, if you like the gold or silver look, that’s just a bonus!)

Make sure to subscribe to our YouTube channel, as in the coming weeks, we are going to be filming multiple testing videos on heat reflective tape, such as gold v bare aluminium piping, gold vs silver and multiple layers of gold reflective to show the difference in degrees and percentage before and after using it.

If you would like to see how you can quickly and easily install heat reflective tape without getting creases, make sure to watch our video below.

Shop Reflective Tape and Sleeving →

4. Myth: Only track cars need heat management

It’s easy to assume that heat wraps, blankets, and other thermal protections are only necessary for 1000hp race cars or track builds.

The thinking usually goes something like this: “My car is mostly stock, and I just drive on the street, so I don’t need any of that fancy heat management”.

In reality, any vehicle can benefit from controlling engine bay heat, especially modern cars with tightly packed engine bays (and certainly any turbocharged car, even factory stock).

While it’s true that a lightly driven daily isn’t going to require as extensive heat shielding as a race car, the basic principles still apply: lower under-hood temperatures can improve reliability and performance on any car.

Even daily drivers see advantages. For instance, many factory turbo cars run very hot under the bonnet. Have you looked under the bonnet of a stock Focus ST or Subaru WRX after a hard drive?

Lots of plastic bits are crammed in there, absorbing heat. By adding a turbo blanket or a small heat shield on a daily-driven turbo car, you can prolong the life of plastic engine covers, wiring looms, ignition coils, etc., by keeping them from getting heat-soaked on every commute.

As a low-powered daily driver, often the temperatures are much less than a high-horsepower track car, but heat management is always relevant, as any engine can produce heat, and in some cases, massively excessive heat.

We’ve had customers with completely stock turbo cars report that after installing some heat sleeves on wiring, and reflective heat tape on their intakes, they noticed things like lower intake air temps during summer traffic, or that their cooling fans kicked on a bit less often.

To learn more about heat reflective tape, watch our video below where we explain it in depth, material composition and the best ways to install it.

It’s not night-and-day like a race car, but it’s a noticeable improvement, and any improvement is a win!

On the flip side, if your car is heavily modified or you drive it hard (weekend drives, track days, etc.), heat management becomes even more critical.

But don’t think “I only have 200hp, I don’t need this.” Remember that manufacturers design the stock heat shielding to be just adequate for normal use and to save cost. There’s usually room for improvement.

Reducing engine bay heat can help prevent heat soak (so your car doesn’t lose power after it gets hot) and maintain more consistent performance. Plus, keeping hoses and electronics cooler will help them last longer, which is important in daily use, where you want the best lifespan possible.

If it is a daily driver, though, as you aren't having any problems and the factory heat shields are keeping the heat in check, you don't need to spend money unnecessarily.

Heat management is designed for exactly that: to manage heat.

If the heat is already being managed well enough, you won't need anything extra, but it's always worth keeping it at the back of your mind in case you do ever encounter an issue.

The bottom line: Heat management isn’t only for race cars. Street cars benefit too; maybe not to the same extreme degree, but every little bit helps, especially if you live in a hot climate or have a turbo.

Our philosophy is that if you can easily add some extra protection (like a wrap, blanket, or heat reflective shield), why not do it?

It’s cheap insurance for you. In fact, many of our products are designed to be easy to install and unobtrusive, so you can set them and forget them in your daily driver.

We’ve seen plenty of sleepers quietly running turbo blankets and heat wraps because their owners care about keeping things cool and reliable.

5. Myth: The factory heat shield is enough

This myth moves on perfectly from the last section regarding factory heat shields.

This myth comes up a lot: “If turbo blankets or exhaust wraps were so great, car manufacturers would put them on at the factory. Since they don’t, aftermarket heat management must be unnecessary or unsafe.”

It’s an understandable thought, but it overlooks how manufacturers make decisions. Car makers are balancing cost, mass-production, warranty, and average user behaviour. A thick turbo blanket or intricate exhaust wrap might indeed lower engine bay heat, but it also adds cost and complexity.

Car manufacturers often opt for simple stamped metal heat shields because they’re cheap and “good enough” for most drivers.

Those stock shields do reduce some radiant heat, but they are a far cry from what a custom-fit turbo jacket or full manifold wrap can do.

For example, the typical OEM turbo heat shield leaves gaps and doesn’t insulate the entire housing, where heat still spills into the bay. A well-fitted turbo blanket, on the other hand, forms a 360° barrier, containing much more heat.

If you currently have a factory turbo car with a basic heat shield, a good test is to use an infrared thermometer or thermal imaging camera, and you will see exactly what we mean.

Also, manufacturers have to consider the worst-case scenario and minimal maintenance. A turbo blanket on a car that never gets inspected could, in rare cases, become oil-soaked if there’s a leak, which is a fire hazard.

Rather than trust every owner to be diligent (such as most modified car owners), they leave it out.

They’d rather your engine bay run hotter (which generally just makes the car a bit less efficient) than risk a poorly maintained blanket causing an issue. It’s always a balancing act, but a much more conservative approach to the matter.

However, many high-performance and racing divisions do use advanced heat management. Look at motorsport or supercars, you’ll find thermal blanketing, ceramic coatings, and gold foils liberally used to control heat.

Those teams and engineers know that to extract maximum performance and reliability, the basic heat shields aren’t enough. Your average road car is built to a cost and to meet broad conditions, not optimised for heat reduction.

That’s where we enthusiasts can improve things with aftermarket products.

We should mention that some modern cars are starting to include better heat management as turbo engines become more common (for instance, some BMW and Porsche turbo models have factory turbo blankets or thicker insulation on certain wires).

But for the vast majority, the stock setup is the bare minimum. If you’re pushing your car harder than average or have power modifications, the OEM heat shielding often isn’t sufficient to prevent heat soak or component wear.

So don’t be fooled into thinking aftermarket heat products don’t work just because your car didn’t come with them.

Many effective upgrades aren’t OEM-installed.

Manufacturers also assume the car will remain stock for its lifespan, which in the modified car scene is never the case.

The moment you increase boost, add power, or drive in extreme conditions, you’re beyond what the factory heat shields were designed for. We usually advise using the OEM shields as a starting point, but don’t hesitate to supplement them with better solutions if they start causing you problems.

We have many customers who keep the factory metal shields and add wraps/blankets on top for maximum heat control. That synergy can drop temperatures dramatically versus OEM shielding alone.

A good video to demonstrate this is one of our newest videos (at the time of writing), where we cut up our old AWD Honda Civic engine loom and tested it with a blowtorch before and after installing a silicone heat sleeve.

This was a very extreme test, but it shows that in the worst case of a fire, or being very close to an exhaust manifold, the silicone heat sleeve would have still protected the wiring perfectly fine.

6. Myth: All heat wraps, sleeves, and blankets are basically the same

“A wrap is a wrap, a blanket is a blanket, I’ll just buy the cheapest one on eBay, they’re no different.”

We hear this a lot, and unfortunately, it’s just not true.

There are big quality and performance differences in heat management products. The materials, weave tightness, insulation thickness, and temperature ratings can vary wildly.

For example, the cheapest exhaust wrap might use lower-grade fibreglass that starts to fray or turn to dust after a few heat cycles, whereas a premium titanium-infused wrap will last much longer and handle higher temps without breaking down.

Similarly, turbo blankets come in different designs: some have multiple-layered insulation (silica fibre, ceramic wool, etc.) and robust stitching with stainless steel or Kevlar thread, while others are just one thin layer of fibreglass cloth.

The cheap ones might initially fit, but they often show hot spots, or the thread can burn, and the blanket falls apart over time.

You can usually tell the difference straight away between a cheaper or expensive turbo blanket at a simple glance from the materials used.

The higher end of the turbo blankets (like our Exoracing V3 blanket) have an inner layer, a thick insulating middle, and a durable outer layer with mesh reinforcement, plus strong seams.

Cheaper ones sometimes skip the mesh or use a filler that isn’t truly rated for continuous extreme heat. As a result, they won't reduce temperatures as much (less insulation = more heat leaks out) and may degrade sooner.

In one case, a customer came to us after a cheap £30 blanket literally singed and falling to pieces after a couple of track days; it simply wasn’t up to the temperature of his turbo. We set him up with our proper unit, and it’s been holding strong since.

Heat sleeves for wires and hoses also differ: the best use materials like silicone-coated fibreglass or reflective aluminised fabric that can take oil, dirt, and high heat without breaking down.

Cheaper sleeves might melt, or the Velcro might unstick when exposed to real under-hood conditions.

In short, you get what you pay for to an extent.

That’s not to say you must buy the most expensive option on the planet, but do a bit of research before you choose to buy anything.

We design and test our Exoracing heat management line to meet certain standards because we want to use it on our own cars, and are absolutely against selling anything we wouldn't use.

When you buy from a reputable heat management brand, whether it's us or not, makes no odds; you’re getting proven temperature reductions and durability that have been verified, so make sure to shop around and choose the brand that you think will get you the best results.

If you go ultra-cheap, you might end up buying twice (or worse, thinking “heat wraps suck” when really it was just that one low-quality product that underperformed).

Investing in a decent turbo blanket or wrap will pay off in actual heat reduction and will save you money long term from not having to consistently replace them.

A good video to explain this is our "how to install a turbo blanket video", where we had our Exoracing turbo blanket on Scott's Honda Concerto for 2.5-3 years and halfway through the video, we inspect it, and it looks virtually new.

Minus discolouring on the inside over time, which naturally happens, he didn't need to replace the blanket, and we still actually have the exact turbo blanket in our office to show customers who visit!

Also, installation of products such as silicone heat sleeves can be done in a matter of minutes!

7. Myth: If the engine is not overheating, engine bay heat is not a problem

Now on to the final engine bay heat myth!

Some people gauge everything by the coolant temperature needle.

“My engine temperature is fine, so who cares how hot the engine bay gets? It’s not an issue unless the car is literally overheating.”

This myth overlooks the many other effects of high engine bay heat. Your coolant gauge could be steady at 90°C, but meanwhile, under the bonnet, it might be 60–70°C above ambient, heat-soaking all sorts of components.

Engine bay heat is about more than just the coolant/engine temperatures. For instance:

-

Intake Air Temperature (IAT): The hotter your engine bay, the hotter the air going into your intake (unless you have a perfect cold-air feed). Hotter intake air = less dense oxygen = less power. Most modern ECUs will often pull timing if IATs get too high, directly reducing performance. Ever notice the car feels sluggish on a hot day or after sitting in traffic? Heat soak is why. Lower engine bay temps help keep IATs lower, which in turn keeps power.

-

Electronics and Wiring: Many sensors, the wiring harness, ECU boxes, ignition coils, etc., live in the engine bay. Excessive heat can shorten their lifespan. Plastic connectors can become brittle, wiring insulation can degrade, and components like alternators can run less efficiently if they’re heat-soaked. Keeping the engine bay cooler (even by a few tens of degrees) can significantly extend the life of these parts. We’ve seen coil pack plastic that literally cracked from years of baking near a hot turbo, and it is something a simple heat shield could have prevented.

-

Fuel System: In extreme cases, too much heat can cause fuel in the lines or rail to get near its boiling point, leading to “vapour lock” or pressure drops. This is more of an old carbureted car issue, but even modern systems don’t love super hot fuel. We use heat sleeves on fuel lines that run near engines as cheap insurance. Lower engine bay heat = happier fuel system, especially on hot restarts. We actually added a Haltech dual-pressure sensor into our Civic fuel rail to measure the pressure and temperature of the fuel, so we know exactly what's going on with the fuel at all times, as it's important!

-

Comfort and Other Components: A cooler engine bay can mean less heat soak into the cabin (ever feel the footwell or centre console getting warm? That’s engine bay heat creeping in). It also means hoses, belts, and even paint on the hood suffer less. Rubber and plastic parts around the engine will simply last longer if they aren’t constantly cooked. When you see firewalls being wrapped in gold reflective tape, this is exactly why. To keep the cabin heat under control, as it's causing problems, or could in the future.

So even if your coolant temp is under control, reducing engine bay temperatures is also just as beneficial.

It’s not about preventing immediate overheating (well, not in all cases anyway), it’s about effects over time and keeping performance stable. Think of it like this: your cooling system (radiator, fans) only manages the engine’s internal temperature.

But all the waste heat from the engine has to go somewhere, and a lot of it ends up radiating around under the bonnet.

By using heat management products to contain or deflect that heat, you help that waste heat exit out the exhaust or out the bottom of the car, instead of saturating everything under the bonnet, or at the bare minimum, keeping important parts protected.

In summary, a normal coolant temperature doesn’t mean everything is peachy and perfect in the engine bay.

Lowering ambient under bonnet heat is always a plus for all of the reasons above. It’s one of those things where you might not notice an issue until you fix it and realise what you were missing.

Many of our customers are amazed at, say, how much cooler their intake pipe or strut tower feels to the touch after adding heat wraps/blankets, which is a clear sign that less heat is soaking into the chassis and components.

Your engine bay can be perfectly reliable and make better, more consistent power when it’s kept cooler, even if it was never technically overheating to begin with.

Real Stories from Exoracing customers

Here are a few real-world outcomes you should expect when heat is managed properly. Your results will always depend on layout, airflow, and how close sensitive parts sit to heat sources, but the direction is always the same.

These stories, though, are directly from three of our customers whom we have dealt with directly to fix their issues (and I can remember, as there have been hundreds of issues like this).

Saved Braided Oil Line on a 500whp Integra

One of our good customers, Liam, who owns a 500whp Honda Integra Type R (DC2), came to us to supply parts to help totally rebuild his engine and went to town building a fully sleeved engine with forged internals.

Due to how the breather system was located on the rocker cover, he started to slowly smell burning, which was due to the braided breather hose being too close to the exhaust manifold.

We have a simple fix for this: supply him with a few metres of our high-temperature silicone heat sleeve, and once installed, it completely cured the problem. He ended up also slightly rerouting the lines aswell just to ensure maximum life from the hoses, and to keep the breather hoses completely protected long term.

The sleeve kept the radiant heat from the exhaust manifold and turbocharger off the line, preventing a repeat failure. It’s a great example of a relatively small investment avoiding a potentially catastrophic issue (oil fires are no joke!).

No More Melted Coolant Reservoir in a K-Swap Concerto

Our friend Scott’s K-swapped Concerto had a turbo positioned uncomfortably close to the plastic windscreen washer bottle.

Before heat proofing, that bottle got so hot you could smell warm plastic, and he actually lost the fluid due to the heat melting a hole through the reservoir.

We fitted one of our Exoracing turbo blankets on his turbo and added some gold heat reflective tape on the side of the washer bottle facing the turbo.

The outcome: after 3 years of spirited driving, the washer bottle is perfectly intact with zero melting or warping, and he only used a small section where the heat was at its maximum.

The combination of the blanket and tape kept the radiant heat away, and the bottle never even discoloured. That’s a real-life improvement for simple mods, which took minutes to install.

Sam's Honda S2000 Master Cylinder Issues

The last story here would be Sam and his turbo K-swapped Honda S2000. So, due to how the swap worked and the custom design of the exhaust manifold, it was sitting right up against the clutch master cylinder (as you can see in the video below).

He already melted one cylinder entirely, so to fix the problem, we sorted him out with some of our aluminium heat barrier to put between the manifold and the clutch cylinder.

This 100% solved the issue, and he hasn't melted another one since. We also recommended wrapping the manifold, but due to his wanting to redesign the manifold in the future, and the fact that the cylinder has now been fine for over a year, he decided not to for the moment.

Since the video, he has installed one of our turbo blankets to reduce the temperatures at the front of the engine bay, which seems to have made a significant difference.

Conclusion

Managing engine bay heat doesn’t have to be complicated or reserved for hardcore racers.

As we’ve shown, many of the scary stories out there are just myths. In reality, with the right combination of wraps, reflective tape, heat sleeves, and turbo blankets, you can dramatically lower your under-hood temperatures and protect your car’s vital components.

Cooler intake air means more power, protected wiring means better reliability, and avoiding heat soak means your car performs consistently, whether it’s the first pull or the last lap.

The key takeaway from reading this (if you have gotten this far) is that heat management is a smart way to easily improve almost any build.

It’s proven (backed by both physics and our own testing), and it can be tailored to your needs, from a simple length of sleeve on a vulnerable hose to a full-suite approach on a high-horsepower project.

Plus, these upgrades often install with basic hand tools in your garage and are designed to be a do-it-yourself project solution. In a weekend, you can completely transform how your engine bay handles heat.

So don’t let outdated myths stop you from keeping your engine bay cool.

Whether you’re aiming for protected hoses in your daily driver or chasing peak performance on the track, controlling engine bay heat is a surefire way to get more out of your car.

We hope this guide has shed light on what’s fact and what’s fiction when it comes to under bonnetheat.

Now it’s your turn to put that knowledge to work and enjoy a cooler, more reliable driving experience!

If you are interested in any of the products we have spoken about in this article, we have all of them in stock, and it massively helps us to be able to create more content like this, whether it's product testing or just plain old myth-busting!

Shop the Exoracing Heat Management Range →

Related products and internal links

If you would like to either shop for any of the products we have available or would like to read more about heat management, check out some of the links below.

Related reading:

- 6 Ways to Reduce Engine Bay Temperatures

- 7 Engine Bay Heat Problems With Simple Solutions

- Conduction, Convection and Radiant Heat Explained

About the author

I’m Matt, the owner of Exoracing Ltd, a UK-based performance parts brand specialising in heat management and performance parts.

Since 2018, we’ve helped thousands of car enthusiasts and workshops reduce engine bay temperatures with tested, proven products all backed by firsthand experience from our own and customers’ builds.

Got questions about your setup? Message us on Instagram @exoracinguk or hit the contact button at the top, as we love hearing about your builds and helping out where we can.