6 Ways To Reduce Engine Bay Temperatures

Posted by Matthew Marks on 5th Jun 2025

I'm Matt, the owner of Exoracing. If you're reading this, you've likely dealt with some form of high engine bay heat before or are currently experiencing it, so you've come to the right place.

Today, we'll discuss the six best ways to reduce engine bay temperatures easily using performance heat management methods. By the end of this article, you can choose between the different options and decide which is best for you and your build.

We'll go over six practical ways to reduce temperatures and provide some bonus points at the end to help you get the most from your build.

We will cover exhaust wrap, turbo blankets, heat shields, reflective tape, hose sleeving, ceramic coatings, and, to finish up airflow.

High engine bay temperatures can reduce power, damage components, and even cause failures due to melted wiring, among other issues.

High-performance builds, such as turbo cars, track or drift machines, and even modified street cars, need effective heat management.

Each method works differently and is suited to different goals. This guide explains how each solution reduces heat, when to use it, and its pros and cons, along with tips from real-world applications.

1) Exhaust Wraps (Headers & Manifolds)

Let's move on to the first section here: exhaust wrap!

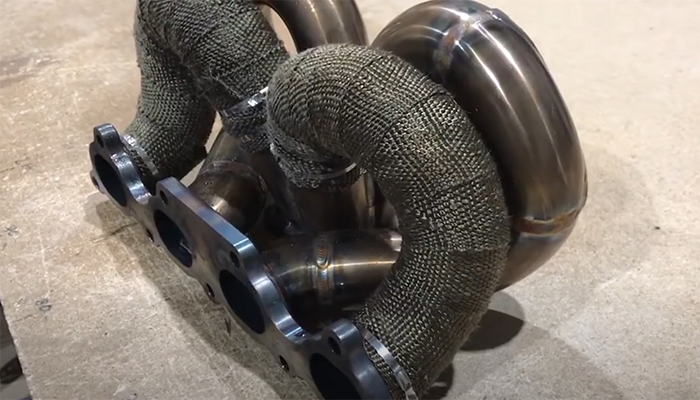

Wrapping manifolds or downpipes with heat-resistant wrap or sleeves is one of the most popular methods to reduce engine bay heat.

The exhaust wrap (typically made of fibreglass, or basalt fibres) will contain the exhaust heat inside the pipes, dramatically reducing radiant heat in the engine bay.

In effect, the exhaust gases stay hotter, which improves flow and slightly boosts power.

Wrapped exhaust manifolds can significantly reduce under-bonnet heat, which is why they are at the top of our list of heat management techniques.

That cooler engine bay will protect sensors, wiring, and fuel/engine components from heat soak.

What is radiant heat?

It's essential to define what radiant heat is before proceeding, as we will be referring to it multiple times in the following article.

Radiant heat is heat that comes from hot engine parts like the exhaust or turbo. It travels in invisible waves, like the heat from the Sun.

Even if the air in the engine bay isn't extremely hot, this radiant heat can still warm up nearby parts, such as hoses, wires, or air filters.

That's why we use heat shields to block the heat. This helps keep the engine bay temperatures down and protects those parts from overheating.

Alright, back to exhaust wrap: how it works and its pros and cons.

How exhaust wrap works

Exhaust wrap is a thick, low‑conductivity blanket around the exhaust pipes. Its fibres will reflect much of the pipe's heat.

This blocks radiant heat by slowing heat transfer through the pipe wall, keeping the exhaust gas hotter and boosting turbo or flow efficiency.

In short, the exhaust wrap shields all heat coming from the exhaust, thereby protecting the components.

When To Use Exhaust Wrap

Exhaust wrap is ideal on turbo or naturally aspirated exhaust headers and long pipes.

Street, track, and race cars use exhaust wraps to protect intakes and electronics.

It's especially common on turbo downpipes and exhaust manifolds, as these generate far more heat than any other place.

Pros |

Cons |

|

Significant temperature drop: Can lower bay temperatures by tens of degrees (as high as ~50% reduction in radiated heat). |

Corrosion risk: The wrap can retain moisture against the pipe, accelerating rust, which is more common with lower-grade materials. In the higher end of exhaust manifold materials, this becomes less of a problem. One thing to note here is that if you decide to wrap your exhaust, do not wrap it all the way to the back, as the further you go, the colder the exhaust becomes. The higher the chance of it retaining moisture, which in turn degrades the exhaust. We recommend running it on the manifold and downpipe for the most effective heat reduction and long-lasting effect. |

|

Performance gain: Improved exhaust scavenging and velocity often yield a slight boost in torque/horsepower. |

Durability: Fibreglass wraps can fray or degrade over time due to vibration and heat cycling. In harsh use, they may become brittle and shed fibres. |

|

Protects parts: Sensors, wiring, intercoolers and the cabin compartment stay cooler, reducing component wear over time. |

Maintenance: Wrapping must be installed carefully; gaps or loose sections reduce effectiveness. It may need replacement every few years on a daily driver if not installed correctly. |

|

Relatively inexpensive: Exhaust wrap is a low-cost and widely available option. DIY installation (wrapping and zip‑tying) is straightforward and uses very few tools. If you need to learn how to install exhaust wrap, we have a video below and blog to guide you through the process. |

Installation time: Wrapping a full header requires a fair amount of work, including maintaining a tight overlap and using stainless ties. Incorrect installation can lead to hot spots. Make sure to reference our video above if you need help with the best practices on how to install exhaust wrap. |

Overall, exhaust wrap is a highly effective and low-cost heat-management step. It's easier to do than a ceramic coat and cheaper than a complete shield kit.

For example, our Titanium or Carbon Exhaust Wrap features a durable, fibrous wrap with stainless steel ties included, making it suitable for use on exhaust manifolds or downpipes.

Unlike flat heat shields, exhaust wrap hugs the pipe closely and effectively battles all heat transfer modes, especially radiant heat.

2) Turbo Blankets

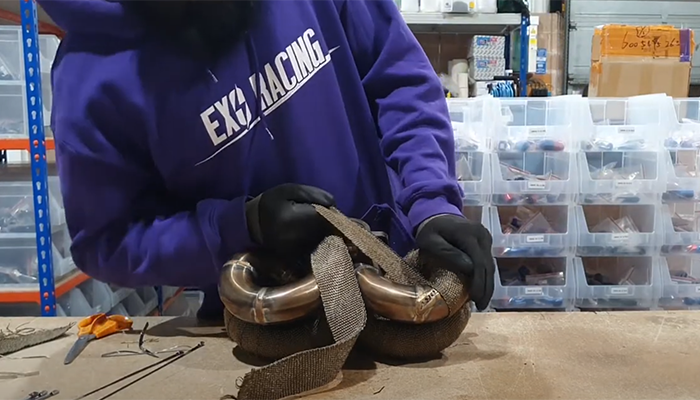

A turbo blanket fits over a turbo's exhaust housing and seals in the turbine's heat, preventing it from soaking into the engine bay.

In turbocharged engines, the turbocharger exhaust housing is the hottest part of the bay. A turbo blanket (also called a heat shield jacket) encases the hot-side turbine housing with multiple insulation layers.

By keeping that heat contained, the blanket stops that radiant heat from heating the engine bay. The hotter exhaust gas trapped inside actually spins the turbo slightly faster (so spool‑up is quicker and lag is reduced somewhat).

Cooler intake air temperatures also result in improved power.

How A Turbo Blanket Works

A quality turbo blanket uses high‑temperature fabrics such as silica insulation wool, carbon or titanium weave and a stainless steel wire mesh inner liner.

It tightly wraps the turbo's exhaust housing, so heat must conduct through thick insulation to escape.

The thick insulation dramatically cuts radiant and convective heat coming from the turbo and soaking into engine bay components.

Essentially, it forms an insulating jacket around the hottest component of the engine. The trapped heat makes exhaust gas move faster, as hotter gases are less dense, which can slightly improve the turbo spool.

When To Use A Turbo Blanket

In any high-boost build (street, track, or drag), turbo blankets are the most common.

They are especially valuable on daily drivers or racers with downpipes routed through the engine bay. Even OEM turbos often have flimsy shields; aftermarket blankets, like our Exoracing V3 Turbo Blanket, provide a genuine, consistent barrier.

Pros |

Cons |

|

Lower intake and bay temperatures: By insulating the turbo, the intake air charge stays cooler, and the engine bay air is also cooler. |

Engine bay space: A turbo blanket occupies engine bay space, which is usually a minor issue. |

|

Performance gain: A slightly faster turbo spool and reduced intake air temperatures. |

Degradation: Over many heat cycles, cheaper blankets can stiffen, crack, or lose their insulating fibres. Higher-end versions feature metal mesh, thicker insulation and coated fabrics to improve durability. |

|

Component protection: Reduces heat damage to nearby coolant lines, hoses, and electricals. Also safer for mechanics (less burn risk). |

Cost: Good turbo blankets will cost upwards of £100, more than plain exhaust wrap. (However, they're still cheaper than engine swaps or intake mods needed to offset high IATs!) |

|

Easy installation: Most blankets slip on and secure with springs or cable ties. High quality turbo blankets are reusable and removable (Check out our video below). |

Fitment: Select the correct size and shape (e.g., T3 vs. T4) for a snug fit. An ill-fitting blanket will be far less effective as there will be gaps around the core. |

|

High-temperature rating: Good-quality blankets use materials rated to 1200°C or higher. |

To show how easy it is to install the turbo blanket, have a look at our turbo blanket installation below and our blow torch testing video to show how hot they can get without burning or losing structural integrity.

In practice, almost all turbo street and track cars benefit from a turbo blanket going through all of the points above. Along with the safety and performance benefits, there aren't many reasons not to run one.

They are hard to beat for a small investment, especially on high-boost setups where keeping temperatures down is a must.

3) Heat Shields & Reflective Barriers

For areas where exhaust wrap or turbo blankets cannot be used (such as between the exhaust and firewall), rigid or adhesive heat shields are used.

These are panels, mats or tapes, often made of aluminium, fibreglass, or both, that reflect or block radiant heat. A proper heat shield can reflect up to ~80-90% of radiant heat away from sensitive components.

For example, a foil‑backed firewall pad or floor liner will bounce most of the hot engine heat back out. We actually have the perfect example of this with one of our friend's K-swap S2000 builds, which we filmed for our Exoracing YouTube channel.

He was experiencing problems with the clutch master cylinder, as the exhaust manifold was very close and was melting the O-rings and piston inside the cylinder.

It also melted through the actual cylinder itself on the second one he installed. He then installed an aluminium barrier after the 3rd master cylinder, and it completely solved the issue!

I'll add the video here for you to take a look at if you're interested. It's also an insane build where he did all the work himself, and at 540bhp, it makes all the right turbo noises!

Types Of Heat Protection Shields

-

- Sheet or Blanket Shields: Stiff aluminium or composite sheets mounted on the firewall, transmission tunnel, or underneath the bonnet. They act like a mirror against radiant heat.

- Adhesive Foil Pads: Peel‑and‑stick tapes or sheets (like our Exoracing Gold or Silver Reflective Sheet and Tape) that stick to panels, piping or wires. Their shiny surface doesn't absorb the heat from hot engine parts. Instead, they reflect it away, keeping nearby parts cooler.

- Custom Shields: Pre‑formed panels for battery trays, pedal boxes, fuel tank covers, etc. These create an air gap and a metal barrier, usually aluminium, between the exhaust and the parts. We use aluminium over steel here because it's lightweight, removes heat faster than steel, and is much easier to mould into the specific shape you want.

How Heat Shields Work

These heat shields stop most of the heat that comes from hot engine parts.

An aluminium shield doesn't absorb much heat, so it keeps the engine cooler or the part that it's protecting. If there is airspace behind the shield, it also stops conduction (air is a poor conductor).

Conduction occurs when heat travels through a material by direct contact.

For example, if you touch a metal spoon that has just been in hot soup, the heat travels from the soup through the spoon and into your hand.

In a car, heat can move more easily from hot parts to cooler parts if they're touching.

In some designs, shields are fiberglass‑backed for insulation on the engine side while reflecting heat outward.

When To Use A Heat Shield

Anywhere hot exhaust runs near fragile parts.

Common spots: firewall behind headers, the underside of the bonnet (to protect paint and sensors), drive-by-wire modules, fuel lines, or transmission tunnels. A heat shield is especially useful in turbo cars for the firewall behind the turbos or along the chassis.

Pros |

Cons |

|

Very effective at blocking radiant heat: With minimal thickness, a reflective panel stops most thermal radiation. |

Coverage limits: Shields only block radiation. Hot air can still flow around them (convection). Also, a heat shield won't help if it touches the exhaust pipe (then conduction bypasses it). |

|

Durable: Metal shields don't deteriorate like wraps do. They survive heat cycles indefinitely and often come with stainless hardware for the longest-lasting protection. |

Fitment: Custom bending or fabrication may be needed. Bulky shields can also add weight and complexity. |

|

Targeted protection: You can shield exactly what needs it (e.g. a clutch reservoir against the exhaust manifold). |

Installation: Attaching a panel close to moving parts requires care (clearance, mounting points). Low-quality adhesive shields can peel off with heat or moisture over time. |

|

Sleek look: Many racers use polished shields for a tidy engine bay. |

Cost: High-end shields, such as those made from titanium or aluminium honeycomb, can be pricey. |

For example, aluminised padding under the bonnet is standard to protect the paint and windshield from radiant engine heat.

Our Exoracing reflective tape and sheets (gold/silver foils) are thin versions of these shields – ideal for wrapping firewalls, lines, and sensors, which we'll go into in the next section.

A properly installed heat shield can complement exhaust wraps: you can wrap the pipe and shield the wall facing it for maximum effect.

4) Reflective Tape & Hose Sleeving

Beyond big panels, heat-reflective tape and high temperature sleeving protect specific parts.

Reflective heat tape is a self-adhesive aluminised film that can be wrapped around hoses, intercooler piping, fuel lines, or A/C pipes. Likewise, sleeving (fibreglass or silicone covers) can sheath wires and hoses.

These products reflect radiant heat and add insulation.

We actually have a comprehensive video that covers what reflective tape is, how it's made, and a range of other features. If you're interested, I'll add it below.

Why Use Hose Sleeving

Thin hoses, wiring, or sensors often lie close to exhaust tubes or turbo housings.

Exposed plastic or rubber will degrade rapidly if left in the heat. Wrapping these with a reflective foil or silicone heat sleeve blocks much of that heat.

How Sleeving And Reflective Tape Works

A heat reflective tape is typically a polymer-laminated glass cloth with a heat-resistant adhesive.

It reflects infrared radiation away from the part. A silicone hose sleeve (fire sleeve) is generally made of woven fibreglass or silicone-coated fibreglass that encases the hose.

Some sleeves have an aluminised outer layer. These stop radiant heat transfer and also provide an additional layer of insulation.

you would generally wrap hoses (fuel, oil, coolant) running near the exhaust or electrical wiring harnesses close to exhaust manifolds.

Turbo oil or coolant feed lines often get braided metal shields, but adding a heat sleeve over them provides extra reflection and insulation.

Intake or intercooler piping can also get wrapped in reflective tape to keep intake temps lower.

Pros |

Cons |

|

Easy application: Tapes are easy to stick on, and velcro or sewn heat sleeves slide over lines. They can be trimmed to length using simple tools such as scissors, making the perfect fit simple and easy. |

Limited weight: These are thin materials, so they mainly stop radiant heat. They don't insulate hot pipes as a thick blanket does. |

|

Protects critical lines: Prevents heat damage to fuel rails, rubber hoses, sensor wires, clutch lines, etc. |

Adhesive limits: Cheap tape adhesive can weaken under extremely high heat or when exposed to oil or water. It may peel away over the years. |

|

Cost-effective: Relatively cheap per foot, far more affordable than rebuilding hoses melted by heat. |

Aesthetics: Sticky reflective tape may look less finished than paint or covers. |

|

Flexibility: Velcro-backed sleeves (like the Exoracing Velcro Heat Sleeve) allow for the removal and reuse of other components or cars. |

Electrical grounding: If you cover sensors or wires, ensure the tape or sleeve doesn't short-circuit (some tapes are conductive).: |

To demonstrate the simplicity of installing reflective tape, we filmed a video showcasing the best methods for achieving a smooth finish without wrinkles.

I have seen installations of reflective tape where people try to bend it around corners, etc. However, in the video, we demonstrate all the necessary tools and the best approach to installing it.

I'll add it below in case you are interested and need any help installing the reflective tape.

In practice, most builds employ a combination of methods, such as wrapping manifolds and applying heat sleeves or foil tape to fuel lines.

Our Exoracing Gold and Silver Reflective sheets and tape material serve exactly this role – they can even be adhered to the firewall or floor, providing the surface is clean and non-porous.

Reflective heat tape typically withstands temperatures of up to around 450°C under normal circumstances while also withstanding spikes of up to 1100°C.

In contrast, the silicone heat sleeve is suitable for temperatures of around 1200 °C. These are excellent for spot protection of vulnerable parts.

5) Ceramic and High‑Temp Coatings

High-end race builds often use ceramic thermal coatings on exhaust components instead of (or in addition to) wrap. A ceramic exhaust coating (applied by spray or powder) forms a hard ceramic layer on headers, manifolds, or pipe exteriors.

This layer is a highly effective thermal barrier, as it resists heat from soaking through metal and emits significantly less.

Essentially, it "locks in" heat inside the exhaust, similar to a blanket but permanently bonded.

How Ceramic Coating Works

The ceramic coating (often aluminum-silicate-based) bonds to the metal surface. It has very low thermal conductivity, which reduces heat transfer.

Coated exhaust pipes run hotter on the inside and cooler on the outside, precisely the same as the exhaust wrap works.

A proper coating can reduce radiated heat dramatically, lowering temperatures and accelerating exhaust flow.

When To Use Ceramic Coatings

Best on complete exhaust systems where disassembly is possible (headers, downpipes, collectors).

Standard in race/track/drag cars, show builds, and trucks.

It's beneficial on turbo housings or exhaust crossovers where no wrap can reach. Whenever you want a clean engine bay look or a permanent solution, coatings are the way to go.

Pros |

Cons |

|

Durable, permanent: Unlike exhaust wrap, ceramic coating can't unravel. A quality coating generally lasts the life of the exhaust. |

Cost: Professional ceramic coating can rack up hundreds of pounds, combining material and labour costs. It also requires oven-baking at high temps. |

|

Reduces bay heat: By blocking radiation, it can significantly lower under-bonnet temperatures, similar to other methods on this list. |

Installation: The exhaust must be stripped, blasted, and dried before coating. Turnaround is now longer and not DIY, unlike the other methods on this list (unless you purchase the necessary equipment and tools). |

|

Corrosion protection: The Coating also seals the metal from moisture, reducing the chance of rust. |

Heat soak: Some argue that a thin ceramic coat insulates less than a thick wrap; however, coatings perform well compared to exhaust wrap in heat tests we have seen. We will be releasing a video in the coming months that showcases a direct test between exhaust wrap and ceramic coating. Be sure to subscribe to our channel to stay notified as soon as it's released! |

|

Performance: Similar to exhaust wrap, the hotter gases travel faster, improving flow and torque. |

Not foolproof: If the coating chips or wears off, which is rare with quality work), those spots lose the heat reduction benefit. |

|

Cosmetics: Available in a range of colours, such as black, white, or metallic finishes for a show‑car look. |

The last thing to discuss when it comes to coating would be thermal Barrier Paints.

These are high-temperature aerosol DIY paints, for example, VHT, that also claim to resist heat. They can withstand ~650–1000°C but are typically much thinner than a ceramic coating.

A high-temperature paint will provide some insulation and protect against rust. Still, it won't reduce bay temps as much as a few hundred-pound ceramic coat.

Paints can also fade or peel if not properly cured or applied. They're a budget stopgap rather than an actual barrier, so for optimal performance benefits, we would generally not go down this route.

In summary, coatings offer a "permanent wrap" solution. For example, a ceramic-coated header can drastically reduce engine-bay heat while maintaining a factory look if that's the desired appearance.

For most street and track builds, exhaust wrap provides much of the benefit at a lower cost, but this is generally down to your own personal preference.

6) Airflow(Fans, Vents, Ducts)

The last of the six ways to reduce engine bay temperatures would be cold, perfectly directed airflow.

Insulation and reflection generally only go so far, and circulating cold air is the piece of the puzzle. By removing hot air from the bay, we can cool the components much more effectively.

Common airflow aids include bonnet vents, high-flow performance fans such as SPAL Automotive and air ducts or cold air intakes. For instance, bonnet vents let hot air escape upward, and side scoops let in cooler air at speed.

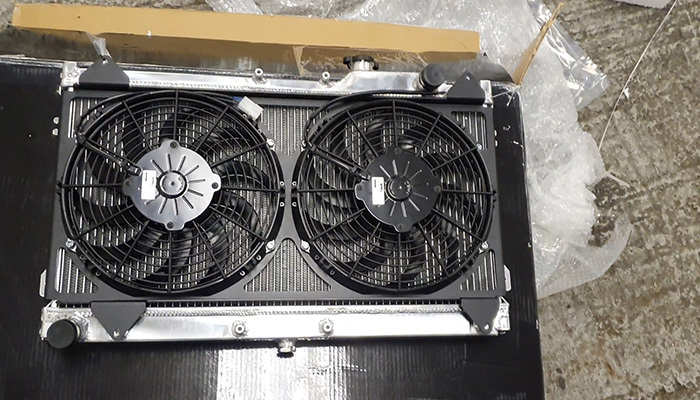

Most cars from the factory use radiator fans to pull air out when the vehicle is stationary or the coolant temperature is starting to rise.

How Airflow Works

Ventilation creates a pressure difference or flow path.

A bonnet vent releases the trapped rising hot air, preventing a heat build-up. Ram-air ducting can force more cool air into the bay at speed.

Essentially, you're reducing heat transfer by keeping the air cool around the engine. Radiator fans work a bit differently; their main job is to keep the coolant in the engine at a specific temperature.

The better the fan's flow, the quicker it can pull the temperature down in the system, which in turn keeps everything around it cooler.

When To Use High Flow Fans

High-power or forced-induction cars on the track or in drift often feature hood vents or ducts. Streetcars can use passive vents (dragging cool air in or letting hot air out at speed).

Extra radiators or transmission coolers can have dedicated fans.

Even adding a second radiator fan that runs after shutdown (like in some race setups) can drive hot air out when you're parked, or you can have the fan set up on a specific switch to do the same thing without the need for an extra fan.

A good example of the twin shroud setup would be Kyms Mx5 where we fitted the T7Design Mazda Mx5 twin fan shroud and did a nifty install guide here:

Pros |

Cons |

|

Real heat removal: Instead of just blocking heat, airflow actually carries it away. This lowers the engine-bay temperature and can also improve intercooler and intake air temperature performance. |

Water/dirt ingress: Vents can let rain and debris into the engine bay, which may require mesh covers or drains. |

|

Prevent stagnation: Especially under the bonnet, keeping air moving avoids heat soak (e.g., water/methanol injection pumps or turbos don't sit in stagnant heat). |

Complexity: Electric extractor fans or custom ducts add wiring, controls, and weight. Bonnet vents require cutting metal and precise positioning to ensure a seamless fit. |

|

No special materials needed: Fans and vents use existing air – no exotic parts. Vents can be cut into stock bonnets or added via aftermarket bonnets, and fans can be added with aftermarket or stock fan shrouds. |

Noise: Higher flow fans can increase noise, and fans draw additional electrical power. |

|

Dual benefit: On cold days, more airflow also helps the radiator's job. |

Marginal at idle: Without motion or fan power, vents do little. Many cooling benefits come with forward motion or fan operation. |

This is common on drift and race cars (where the cooling fans may be sized for the radiator, not the entire bay). Even a few ducts aimed at key hot spots (like the turbo) can shave temperatures.

It is also very common to point towards the air filter or turbo compressor housing to try and draw in the coldest air possible.

In short, airflow mods are in addition to everything else on this list. You'll often see a race car that has both insulated components and bonnet vents. Together, they can cut bay temperatures dramatically.

Bonus: Other Solutions and Tips

- Line/Hose Sleeving: For very close clearance to high heat sources, a silicone fire sleeve on fuel or oil lines adds extra margin. Silicone or fibreglass hose covers (rated to 500–1200°F) can be in close contact with the exhaust manifold without damage. These are simple to slip on where wrapping isn't possible, although it's worth noting that they cannot be touching a manifold.

- Insulating the bonnet Itself: Some cars add a foil-backed insulation pad to the underside of the bonnet. This reflects engine heat away from the paint. It's effectively a giant heat shield just above everything.

- Vented bonnets: A solid surface will trap heat under it. Even stock bonnets can be modified to eject heat.

- Stainless Steel Cable Ties: Wherever you use exhaust wrap or heat shields, use stainless steel ties or clamps. Stainless cable ties won't melt and are commonly used on exhaust wraps.

- Maintenance: After installing wrap or shields, monitor your temperatures with an infrared gun or data logging (if you have an intake temperature sensor and a way to display this data such as a Haltech ECU). Confirm that intake air and coolant temps are lower and add as much or as little as needed. Sometimes, adding one method (such as wrapping the exhaust) reveals a new hotspot, requiring a second solution (like a heat shield or duct).

- Daily vs Track Use: A daily-driven turbo car might benefit most from exhaust wrap and a good turbo blanket, as they provide passive gains. A dedicated race car might add everything to this list for maximum payoff, as it maintains high temperatures for a much longer period.

Conclusion

The most effective engine-bay heat management usually combines all the methods we have discussed above.

For example, a turbo car might have wrapped manifolds, a turbo blanket, firewall shields, reflective tape on lines, and a high-flow radiator fan. Each layer of protection reduces a mode of heat transfer.

All else being equal, always target the hottest parts first: insulate or shield the exhaust manifold and turbo, then protect vital lines, and then improve airflow.

For instance, our range of Exoracing exhaust wraps and turbo blankets can be your first upgrade, as they are easy to install and offer a significant, immediate benefit. You can later add reflective panels or coatings.

Together, these steps will lower intake-air temperatures, in turn boosting power and preserving electronics, fuel, and even cabin comfort.

By understanding the why and how of each solution, you can choose the right mix for your build. Well-chosen products will keep your performance engine cooler, safer, and more powerful.

If you're unsure about anything in this guide, or want to buy any of the parts in this guide, please don't hesitate to get in touch with us. We're more than happy to help you reduce your bay temperatures!