Conduction, Convection and Radiant Heat: How Engine Bay Heat Transfer Works

Posted by Matthew Marks on 14th Jan 2026

Today, we will cover the three types of engine bay heat transfer and discuss how to tackle each one.

If you are reading this, you already know that heat management in an engine bay is important, and we have dealt with nearly every problem over the past 8 years.

We have even faced the exact problems in this guide in our own cars, time and time again, and as I was researching for another article, I realised that we have never actually explained the differences between the three types of heat transfer and which products or methods solve each one, or at least reduce each one.

I am Matt, the owner of Exoracing. Since 2018, we have helped thousands of car enthusiasts and workshops control engine bay heat with parts specifically designed for the job and thoroughly tested.

By the end of this guide, you will understand the three ways heat moves in a car, which are conduction, convection, and radiant heat. Once you understand them, picking the right fix becomes simple. You stop guessing and start solving the real problem quickly and easily.

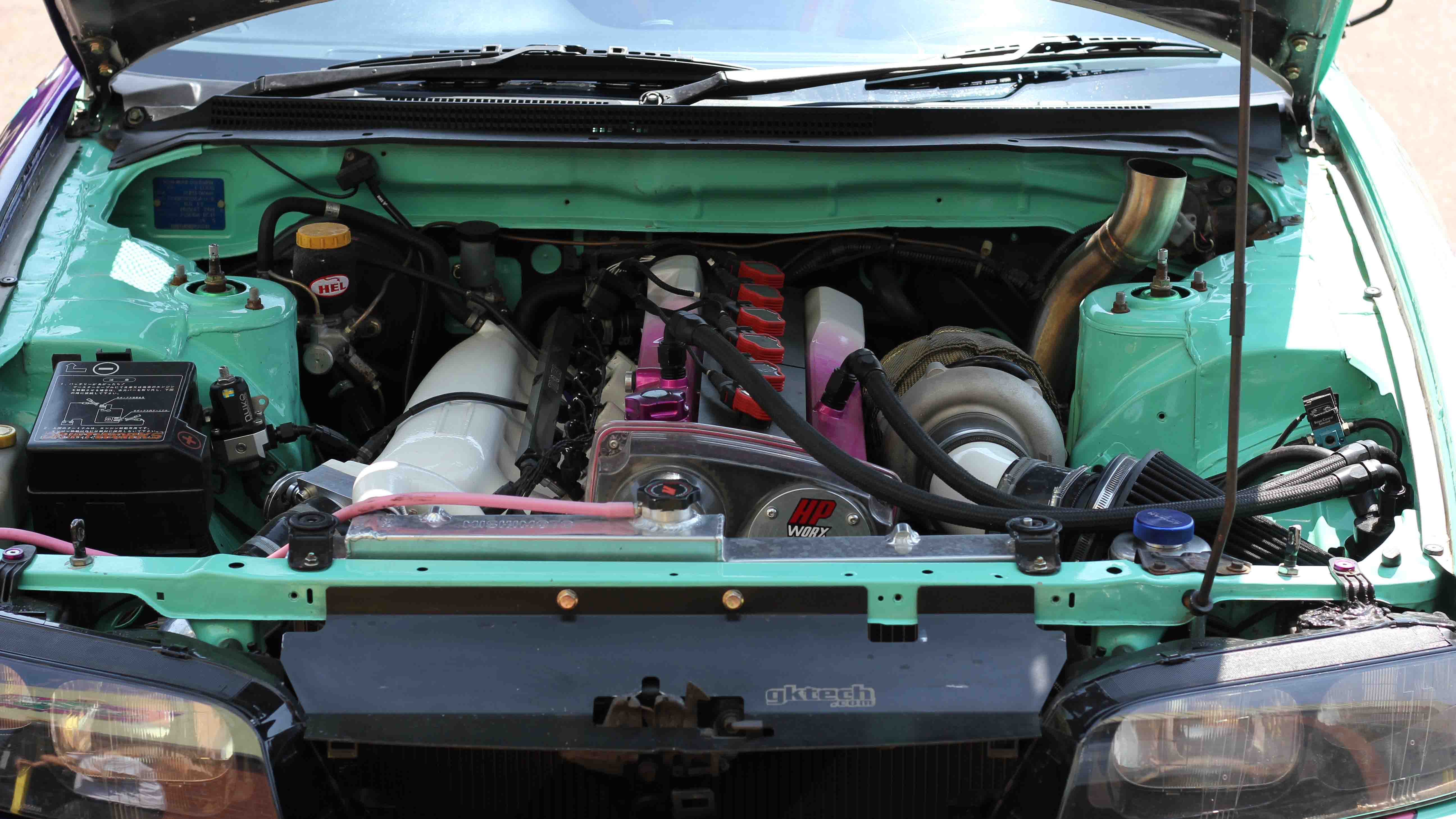

We will break each heat type down in a simple way, show multiple engine bay examples, and link the products designed to tackle each one.

This guide is brought to you by Exoracing, UK specialists in heat management and performance parts.

- Conduction is heat moving through solid parts that touch

- Convection is heat moving with airflow or coolant flow

- Radiant heat is heat that shoots out like an invisible heat lamp

- Reflective tape and turbo blankets fight radiant heat

- Thermal wraps and sleeves slow conduction and reduce heat bleed

- High-flow fans and shrouds improve convection by moving hot air out

Conduction Heat

Conduction is heat moving through a solid object when it touches another solid object. Think about a metal spoon sitting in a hot pan. The handle gets hot because heat travels through the spoon and slowly heats the furthest end of the spoon.

In an engine bay, conduction is happening all the time because most of the parts are metal and bolted together. If one part is hot, it can pass heat into the next part just by touching it.

For example, when your exhaust manifold is hot, if you remove the exhaust studs, they are also very hot.

This is conduction at work, and even though the hot exhaust gas isn't directly touching the bolts, the conduction through the metal heats the bolts.

How conduction happens in an engine bay

Metal is really good at moving heat. That is great for engines in some ways, but it also means heat spreads fast, even when you don't want it to!

When a hot part touches a cooler part, the heat will try to even out. That is why a bracket, a bolt, or a fitting can get hot even if it is not directly in the flame path or not sitting right next to the turbo.

This is also why heat problems can feel random. A part that looks far away can still be getting cooked because it is connected to something hot through a chain of metal parts.

This is where our testing with a thermal imaging camera comes in and how we manage to solve engine bay heat problems.

Even if something doesn't look hot, it might be, and in some of our upcoming tests, we will test multiple engine bay points versus heat management to see if we can not only reduce the temperature of the part we are insulating, but also reduce the transfer around the engine bay.

Real engine bay examples of conduction

- An exhaust manifold heats its bolts and studs, then those bolts heat up the brackets and anything they touch.

- A turbo housing heats the metal oil feed fitting, then the heat travels into the line and into the oil.

- A downpipe touches or sits extremely close to a gearbox mount and slowly heats it over time.

- Metal charge pipes pick up heat where they bolt to the engine, or where they sit near the radiator area.

- A heat shield mounted directly to a hot manifold can conduct heat into the shield mounts and nearby panels.

Why is conduction heat a problem?

Conduction is sneaky because it is constant and it is quiet.

Even if temperatures are not extreme, steady heat transfer can dry out rubber, harden seals, weaken plastic clips, and warm up fluids like oil and fuel, where you do not want extra heat.

On turbo cars, conduction is one of the reasons oil lines and fittings can suffer.

The heat moves through fittings and brackets straight into the line, and we obviously need to reduce this as much as we can.

Products that tackle conduction

For conduction, you want an insulation layer between the hot part and everything around it.

- Exoracing Titanium Exhaust Wrap helps by creating a thick barrier on the pipe so heat stays in the exhaust instead of spreading into the bay.

- Exoracing Silicone Heat Sleeve helps by insulating hoses and lines so heat does not travel through them as easily.

- Exoracing Sewn Heat Sleeve helps protect lines that run near hot metal parts for long periods.

- This isn't so much a product, but choosing specific materials in the engine bay, for example, aluminium rather than a stainless steel intake pipe, will help towards reducing conduction as stainless steel will hold more heat for longer than aluminium will.

Convection Heat

Convection is the process of heat moving fluidly, and in a car, the fluid is usually air or coolant. This is why radiators work well as hot coolant carries heat from the block/head to the radiator, then air carries that heat away, cooling it down by the time it reaches the engine again.

The loop carries on over and over via the water pump and is aided by high-flow fans and directed airflow to try to cool the radiator as much as possible.

Convection can help you or hurt you. If hot air gets trapped under the bonnet, it keeps heating everything. If air moves properly, it carries heat out and stops heat soak.

How convection happens in an engine bay

When your car is moving, fresh air comes through the front of the car and flows through the radiator and around the engine bay. That moving air picks up heat and takes it away.

When you stop, airflow through the bumper drops, and this is normally when the fan kicks in.

The engine is still hot, so the air under the bonnet heats up and just sits there when the fans aren't blowing. That is heat soak in a nutshell, and our job is to try to reduce this as much as possible.

Everything gets warmer, even parts that are not touching anything hot, and in high-performance applications, this is made 10x worse as the heat generated is much higher in the same time period.

This is why when you see racecar engine bays, they will always be using products such as turbo blankets, exhaust wraps, ceramic coating and anything else they can do to try to bring the temperatures down as much as possible.

Some cars run fine on the road but get too hot in traffic.

The problem is not always that the radiator is bad. Sometimes the problem is simply not a high enough airflow, or airflow being diverted the wrong way, and causing more problems than it's fixing.

Real engine bay examples of convection

- Coolant moves through the engine and radiator, carrying heat away from the block.

- Radiator fans pull air through the radiator at idle to stop temperatures from creeping up.

- Hot air trapped under the bonnet after a hard pull, heating the intake and wiring until you start moving again.

- Intercooler and radiator performance change based on how well air is guided through them.

- Turbo cars heat up in traffic because hot air is not being pulled out fast enough.

Why convection heat is a problem

Convection problems usually show up as temperatures rising when you are not moving fast.

You might see coolant temps climb at idle, intake temps rising in traffic, and the whole bay feeling like an oven after a quick stop.

Even if you have great radiant protection like a high-quality turbo blanket, trapped hot air and convection can still make everything warm.

That is why airflow is part of the full solution.

Products that tackle convection

For convection, you want better airflow and better control of where air goes.

- High-flow Radiator Fans pull or push more air through the radiator when the car is slow or stopped.

- Fan Shrouds stop air from escaping around the sides and force air through the radiator core.

- Upgraded Radiators increase the cooling area so heat can leave the coolant faster, and are made from higher-quality materials than the factory versions to dissipate heat faster and more efficiently.

Radiant Heat

Radiant heat is heat that travels like an invisible beam, such as an infrared heater.

It does not need contact, and it does not need moving air.

It is like standing near a bonfire, where you will feel it on your skin even though you are not touching the fire.

Radiant heat is a big deal in turbo cars because the turbo, manifold, and downpipe can get extremely hot. That heat shoots out into the engine bay and warms up anything facing it.

Generally, radiant heat is one of the biggest problems in performance applications and one of the areas we usually focus on.

The exhaust manifold and turbocharger can generate up to 1200°C, and in our turbo blanket test, we actually saw a massive reduction in temperatures from the inside to the outside in our blowtorch test.

I'll show you the video here so you can watch it and see for yourself, but we capped out thermal imaging camera out at 580°C (the propane torch can reach 1900°C) and the hottest on the outside we saw on the day was just over 60°C.

This is the power of using heat management to stop radiant heat transfer in your engine bay.

How radiant heat happens in an engine bay

Any very hot part will give off infrared heat. Think of it like a heat lamp, and if a hose, wire, intake pipe, or bonnet panel is in the line of sight of that hot part, it will soak up heat.

This is why you can have a hose that is not touching the downpipe, but it still gets hot and goes hard over time. It is being cooked by radiant heat.

It will start with the exhaust gas, making the turbocharger and exhaust manifold incredibly hot, then that heat will radiate out of them and start warming up everything else around it.

It isn't just those parts that can emit radiant heat; anything hot in the engine bay can produce this heat, so we will always start with the hottest parts to manage and work our way down to get the most benefit possible.

Real engine bay examples of radiant heat

- A turbo housing radiates heat into the intake pipe, raising intake air temperatures.

- An exhaust manifold radiates heat into wiring looms, sensor plugs, and the firewall.

- A downpipe radiating heat into the driveshaft boots, steering racks, brake lines, or the gearbox casing.

- A hot exhaust section radiates heat into the underside of the bonnet and heats the paint and clips.

- Hot radiator and engine parts radiate heat into the airbox area when parked.

Why is radiant heat a problem?

Radiant heat is the one that surprises people the most because it can heat parts that are not even close and can also cause heat soak.

That means your intake temps rise, your car feels slower due to the ECU pulling timing, and plastic parts get tired faster.

On turbo builds, radiant heat is often the reason you see melted wiring or hoses near the turbo, cooked coil packs, and hoses that fail early.

Products that tackle radiant heat

For radiant heat, you either reflect it away or you contain it via insulation at the source.

Both methods are a good idea, and the more you insulate and reflect heat, the healthier the engine and everything around it will be.

- Exoracing Reflective Gold Tape reflects radiant heat away from panels, hoses, intakes, and wiring.

- Exoracing Turbo Blanket contains heat at the turbo, so less heat escapes into the bay.

- Exoracing Titanium Exhaust Wrap contains exhaust heat and reduces how much of heat that radiates outward.

- Exoracing Velcro Heat Sleeve adds a removable shield over wiring and lines that sit near radiant heat sources.

Why heat problems feel random in real life

Heat is sneaky because all three types are happening at once.

A turbo can radiate heat into a pipe, the pipe can conduct heat into a bracket, and trapped hot air can convect heat into the intake.

That is why the best setups use layers of heat protection. A turbo blanket at the turbo, exhaust wrap on the exhaust, heat reflective tape on nearby parts, velcro or sewn heat sleeve on wiring and airflow to move heat out.

Once you have a full combination of everything, you will dramatically cut the problems that occur with all 3 of the heat types, and your car will thank you long term!

FAQ

Which heat type is the worst in an engine bay?

Radiant heat is usually the one that surprises people. It shoots out from the turbo and manifold and warms up everything nearby, even if nothing is touching.

Also, the turbo and manifold are by far the hottest parts of the engine, so they will always be the worst heat sources in an engine bay.

Luckily, there are multiple ways of being able to reduce this, such as blankets, wraps, ceramic coatings, etc, to try and insulate the highest amount of heat possible.

Do I need reflective tape if I already have my exhaust wrapped?

Most often, yes. Exhaust wrap will help to contain heat at the source, whereas reflective tapes help protect the parts that still sit near the heat source, like wiring, hoses, and intake pipes, by reflecting the heat.

The best option is to insulate heat by using wraps, and reflecting or shielding parts using either reflective tapes or silicone heat sleeves.

Why do my temps climb at idle but drop when driving?

Temperatures climbing at idle are often a convection problem. At idle, there is less airflow, but when you drive, airflow increases from movement and pulls heat out of the engine bay.

Better flow rate fans and a proper fan shroud can help a lot in moving air fast when you are stationary.

Can I just fix the heat with one product?

Sometimes you can, yes, but it usually depends on the severity of the problem.

The best results usually come from layering to contain heat where it is made, reflect it away from sensitive parts, and then move hot air out with airflow.

A combination of every method is by far the best way to fix heat, but if you can only use one product, we would always recommend going with the hottest parts of the engine bay, which are either exhaust manifolds or turbocharger exhaust housings.

Conclusion

Heat management does not have to be confusing. Once you know how heat moves, you can choose the right fix.

There are multiple ways of being able to fix heat problems, and once you understand the 3 different types of heat transfer, you can begin to come up with a plan on how to reduce each one.

In a nutshell:

- Conduction is heat travel through parts that touch, so use sleeves and wraps.

- Convection is heat travel with airflow and coolant, so use upgraded radiators, fans and shrouds.

- Radiant heat is heat beaming out, so use reflective tape, turbo blankets, exhaust wrap or ceramic coatings.

Shop the Exoracing Heat Management Range

Related products and links

- Exhaust Wraps

- Reflective Tape and Sleeving

- Turbo Blankets and Shields

- Radiator Fans and Cooling

- Related blog: How to Reduce Engine Bay Temperatures

About the author

I am Matt, the owner of Exoracing Ltd, a UK-based performance parts brand specialising in heat management and performance parts.

Since 2018, we have helped thousands of car enthusiasts and workshops reduce engine bay temperatures with tested, proven products, all backed by first-hand experience from our own and customers' builds.

Do you have any questions about your setup? Message us on Instagram at ExoracingUK or hit the contact button at the top. We love seeing all of your builds and helping out our readers/customers!