7 Engine Bay Heat Problems With Simple Solutions

Posted by Matthew Marks on 23rd Dec 2025

Have you ever wondered why the small plastic cover over your wiring has faded over time, or why rubber hoses have started to crack?

This is most likely due to excessive temperatures under the bonnet, which are affecting surrounding components.

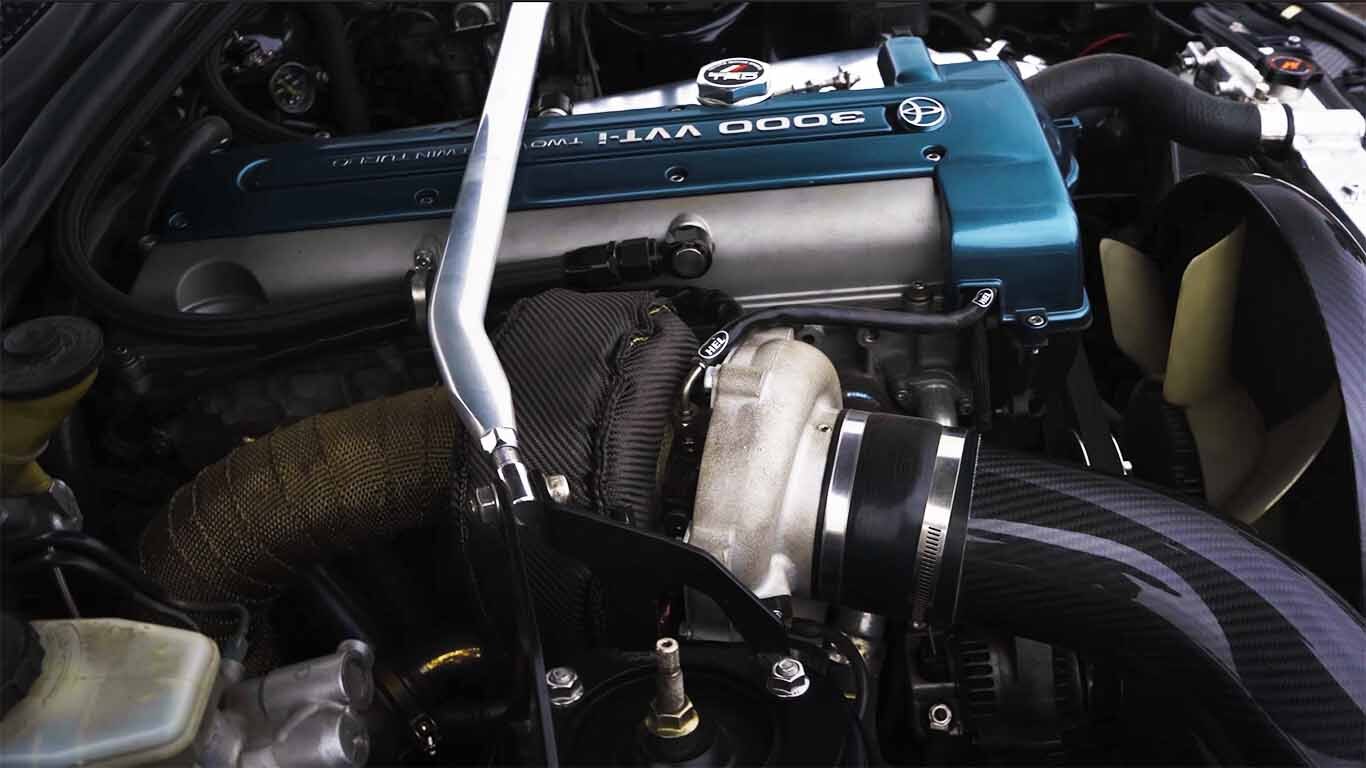

The most common areas are around the turbo or exhaust manifold, as they are the hottest parts of the engine bay.

Too much heat under the bonnet can quietly cook hoses, wiring, sensors, and even performance, without you realising until a hose splits and you leak coolant or get a vacuum leak.

Today, I will review seven common engine bay heat problems and share a simple solution to address them and keep your engine bay components healthy.

I am Matt, owner of Exoracing. Since 2018, we have helped thousands of car enthusiasts and workshops tackle engine bay heat with tested, proven heat management products.

By the end of this guide, you will know the most common engine bay heat problems, their causes, and the simplest ways to protect your setup without expensive parts.

We will review seven real-world problems I have encountered and match each with a practical solution using products such as turbo blankets, exhaust wrap, and reflective heat shielding, as well as methods such as increasing airflow or directing heat away from sensitive components.

- Spot 7 common signs your engine bay heat is getting out of control

- Resolve each issue with a simple heat-management tip or an upgrade

- Protect wiring, hoses, sensors, and performance without big mods

1. Problem: Plastic parts look faded or brittle

Plastic covers, clips, and connectors can fade or crack when exposed to heat over time. This is common near turbochargers, exhaust manifolds, and downpipes, where radiant heat is strongest.

This happens because, although the factory connectors are designed to withstand relatively high temperatures, they were also made with a budget in mind. As engine horsepower increases, components in the engine bay become hotter, as heat is always a byproduct of extra power, and gradually deteriorate.

Also, there is a limit inside the engine bay of where you can physically place a sensor, wiring, or cables. For example, on a factory-equipped B-Series Honda Civic EG, the throttle cable runs over the exhaust manifold.

This is protected by a heat shield over the exhaust manifold, but once you install aftermarket exhaust manifolds or perform a turbo conversion, it becomes an issue.

We had this exact issue with radiator fan shroud wiring. The wiring plug, due to its location near the radiator and repeated exposure to radiant heat, became so brittle that it snapped when we tried to unplug it. We had to replace the connector and relocate it to prevent this from happening again.

There are several wiring, connector, and hose options depending on your proximity to the heat source.

Solutions:

- The most cost-effective solution is to relocate the plug or plastic parts, if possible. Sometimes you can remove unnecessary plastic parts, which is a standard approach to resolving the issue.

- This isn't always possible due to the nature of the plastic parts, so the next best option is to install an aluminium heat barrier between the heat source and the plastic. Because the product is aluminium, it dissipates heat quickly, and leaving a small air gap further reduces heat dissipation.

- If the part you are trying to protect is incredibly close to the heat source, such as a breather hose running over an exhaust manifold within 5-10cm, you would need to use a high-temperature silicone heat sleeve. Our Exoracing silicone heat sleeve has a maximum intermittent temperature of 1200°C, which is more than sufficient for components near high-temperature heat sources.

- If you are further away than this, adding a sewn high-temperature heat sleeve or Velcro heat sleeving is the best option, as they are rated for around 250°C, which is suitable for this distance.

2. Problem: Wiring insulation becomes hard or cracked

When wiring insulation becomes stiff, splits, or appears glossy, heat is often the cause. Once the insulation fails, you may experience intermittent faults that are difficult to diagnose down to the wiring inside perishing. Once you get a split wire, it's often incredibly painful trying to track it down, so the best method is to prevent it before it happens.

If you have always had older cars, you will feel the pain with this one, as I don't think I have ever personally owned a car that hasn't suffered from this, especially vehicles from the 90s.

Wiring sleeving for engine looms has long been used for two main reasons: to keep the loom together and tidy, and to prevent snagging or heat-related issues. The hotter the engine bay is, or the closer the loom is to a heat source, the more this will become an issue.

A few years ago, we had to completely rewrap our engine bay loom on the AWD Civic because the plastic conduit had split in multiple places, causing the car to shut down during a drag-and-drift event.

As you can imagine, this was incredibly frustrating, as we couldn't do anything about it until we returned to our unit and realised it was a single broken wire.

We now have a custom loom installed, built from scratch by Phil at XDR Motors with Raychem sleeving and heat management to prevent this from happening again. If we had addressed this at the time, we would have had a great day and would never have caused the car to shut down.

Solutions:

- Reflect heat away from the loom, and protect areas closest to the exhaust and turbo first. The turbo and exhaust manifold are typically the hottest components in the engine bay, so the best way to address this issue is to stop it at the source. Fitting an exhaust wrap to the manifold and, if you have a turbo, installing a turbo blanket will significantly reduce the temperatures absorbed by the engine bay.

- The next best thing is to wrap the loom in Velcro heat sleeving. This will reflect radiant heat away from the loom and provide an insulating barrier to prevent heat from penetrating the wiring.

- The next solution is to relocate the wiring, as we did on our AWD Civic. I will add the video below in case you are interested. We didn't do this specifically for heat management, but it is a viable solution with some time.

- The last solution is to create a custom loom from scratch, route it through the coolest parts of the engine bay, and heat-sleeve the entire loom to prevent heat-related issues. If you are going to this extent, you will likely already know about heat management, but I thought we would add it here, as it is a viable option.

3. Problem: Rubber hoses fail earlier than expected

Coolant hoses, vacuum lines, and silicone joiners can soften, swell, or split prematurely when exposed to constant radiant heat. You might replace a hose, only for it to fail again months later.

I'm sure we have all been through this before. The most common I've seen would be wastegate vacuum lines. Generally, the lines are made from silicone, which, as a single ply, has limited heat resistance and can either balloon or split easily.

Last month, we actually had a customer with that exact issue. We replaced the vacuum hose for him, and he used a sewn heat sleeve over the hose on his drift Mazda MX-5. The problem has now completely gone away.

Even simple products like this can make a significant difference in whether the hose fails or remains protected over the long term.

You will encounter the same issue with silicone hose joiners for air intakes, intercoolers, and similar applications. If they are next to a high-heat source, such as an exhaust manifold or downpipe, the colour will change over time, and they will become incredibly brittle. Heat, boost, or intake pressure can cause them to fail years before the material is expected to fail.

Fortunately, there are a few methods to prevent this from happening or, at a minimum, reduce it.

Solution:

- The first solution is to stop heat at the source, such as by using an exhaust wrap on a downpipe or a turbo blanket on the exhaust side of a turbocharger. These products will help insulate against heat and reduce the risk of heat transfer to other engine bay components.

- The second solution is to try to reflect the radiant heat away. This is precisely what the customer did in our last example with the vacuum hoses. He installed Exoracing sewn reflective heat sleeves, which are designed to reflect radiant heat away from the hose, preventing the problem from occurring in the first place.

- The third solution is to install a physical barrier, such as an aluminium sheet. This will add a physical layer of aluminium in place, which dissipates heat incredibly well, and you stop the heat in its tracks with air on either side.

- The final solution is to add supplemental airflow to cool the area. If you can install high-power fans or add a duct to circulate air, the heat will not remain trapped, and the area will cool.

4. Problem: Paint and coatings discolour under the bonnet

If brackets, heat shields, bonnet paint, or coatings start to yellow or brown, it is often due to trapped heat or repeated heat soak.

In race cars, you will notice that most of the time they use gold or silver reflective sheeting on the inside of the bonnet. This isn't just about appearance; it will prevent the paint from bubbling or discolouring when exposed to a constant heat source.

Although the reflective rolls and sheets aren't designed for temperatures above 1000 °C, they can reflect up to 80% of radiant heat, which is enough to keep your paint intact and prevent discolouration.

That said, they can definitely help with this and can easily handle up to 450°C, with intermittent spikes up to 1000°C.

If you are going above this, you will want to insulate as well as reflect. Sporadic spikes of up to 1000 °C, but if you are going above this, you would want to insulate as well as reflect.

If you have paint in the engine bay, you may also notice a similar issue here, which is directly linked to temperature-related problems.

We have seen this multiple times on customers' cars, and it seems to be the older performance cars, as back in the day, the heat management wasn't as good as it is nowadays from the factory.

With newer models coming out, manufacturers are considering factors like plastics and specific routing to prevent paint from burning. On older cars, especially those more popular for modification, plastic parts are often removed because they don't look great and can cause problems.

Solution:

- As mentioned above, one of the main products to help is reflective tape. It can usually handle up to 450°C continuously, which is typically higher than the temperatures these areas will encounter.

- If you are encountering significant temperature spikes that cause the paint to bubble, your best option is to increase airflow or use one of the other methods we mentioned, such as exhaust wrap, ceramic coating, or installing a physical barrier.

- Try to contain as much heat as possible at the source, such as the turbocharger and exhaust manifold (i.e. the hottest parts of the engine bay).

5. Problem: You smell hot plastic or rubber after driving

A strong, hot odour after a standard drive is often a sign that heat is penetrating wiring, hoses, or plastic housings. Sometimes it is mild at first, then gets worse.

Don't mistake this for the engine bay being hot after a hard drive; the more you drive the car, the hotter the engine bay will be. Usually, if you smell burning, it needs to be addressed.

Over the past 7 years, we haven't seen this problem very often; it's usually easy to find and, 9/10, it's due to an installation issue or a straightforward fix.

The most common cause is a cable tie or loose hose touching the exhaust manifold, which can melt it.

We actually had this exact problem on our civic just before the mapping session. We were running the breather lines over the turbo exhaust manifold and totally forgot to add a heat sleeve.

The result was a burnt outer layer of nylon braided hoses, which we had to replace. We then relocated the breather hose, routed it in the opposite direction around the engine bay, and installed a silicone heat sleeve, which completely resolved the issue.

Fortunately, it was a straightforward find, as we could see it smoking...

Solution:

- Identify the exact cause of the burning and ensure you haven't accidentally left a loose cable tie or hose in contact with an exhaust manifold. They can reach hundreds of degrees and will definitely melt through plastics, causing smoke and/or a burning odour.

- If nothing is melting, it might be an internal problem, for example, wiring melting underneath the sheathing. Pinpoint the issue and decide on the best course of action past there. Typically, for wiring, a silicone heat sleeve (as in our example) will resolve the issue.

- The simple, free air-source method is the final solution here. The engine bay may be trapping hot air, and a high-flow fan, such as SPAL Automotive fans, could resolve the issue.

Identify the heat source area and apply targeted reflective shielding first. If the smell is near the turbo or manifold area, add a turbo blanket and exhaust wrap.

6. Problem: Heat soak after short trips

Heat soak is when the car feels less responsive after a short drive and restart. Under the bonnet, temperatures rise, intake temperatures climb, and everything feels a bit sluggish.

We will cover heat soak in a future blog. In essence, heat soak is when excess engine heat saturates everything under the bonnet and causes (in most cases) the ECU to counter this by pulling ignition timing, which makes the car slower.

If you are running aftermarket engine management, such as a Haltech ECU, you can see in the intake air temperature log that, when sitting in traffic, the temperature entering the engine continues to climb above normal; this is heat soak.

Fortunately, heat soak is a simple fix and more common than you think.

Solution:

- Keep heat in the right place. As I have mentioned a few times now, keeping the heat at the source and insulated is a great move, as it prevents the heat from reaching the intake in the first place. An exhaust wrap or a turbo blanket would be the most effective option, as they are the hottest parts of the exhaust system.

- The second solution, and by far the most common, would be to fit reflective heat tape to the intake pipe. This can reduce radiant heat by up to 80%, preventing heat soak of the intake/intercooler piping. You have likely seen race cars with their entire intakes wrapped in reflective tape; this is the reason. The colder the air going into the engine, the more power you can make!

- The third solution is to increase airflow to move heat away from the intake piping, which complements the other methods. Still, we always opt for reflective tape, as it's cheaper and one of the most effective ways to combat heat soak.

7. Problem: Parts near the exhaust keep failing first

If sensors, hoses, or wiring near the exhaust repeatedly fail, it usually indicates they are exposed to excessive radiant heat or insufficient shielding.

Earlier in the article, I mentioned our breather hose melting over the exhaust manifold; this was solely due to the exhaust manifold's high operating temperature.

Hundreds of degrees can radiate from the exhaust manifold, and if you aren't careful with wiring routing (or breather hoses in my case), you will melt the wiring or breather hoses.

Another common issue is the lambda sensor wiring. At the factory, most lambda sensors are equipped with heat shielding around the base to prevent this, as OE manufacturers also recognise this issue.

Solution:

- There are only two leading solutions to fix this problem, and we'll start with the free one! Relocate the component that is melting or beginning to cause problems. Usually, if this is wiring-based, you may have enough slack to move it and cable-tie it out of the way; otherwise, you may need to rebuild the loom or extend the wires. This isn't the best method, but it's often free and fast, yielding significant benefits.

- In some situations, relocating the melting component is not feasible so that we will proceed with the next best option. Exhaust wrap or ceramic coating! This is one of the main reasons exhaust wrap and ceramic coating were developed; both have their place. If you prefer the lower-cost option (though it's DIY), the exhaust wrap is the right choice. If you would like someone to sort it for you and don't like the look of exhaust wrap, ceramic coating is a good option. We won't make sweeping claims about one versus the other until we test them with data, but both are widely accepted options.

Wrap the manifold and top of the downpipe to reduce radiant heat, then use reflective tape as a second line of protection for nearby components.

Why heat management works so well

A single major heat event does not cause most engine bay issues. They happen slowly as heat repeatedly soaks into nearby parts. Heat management is about controlling where heat goes, containing it at the source, and reflecting it away from sensitive areas.

There are three types: insulating, reflecting, and airflow (convection).

They all have their place in an engine bay, and some are better suited to specific tasks than others. Ideally, you want to control all 3 to maximise benefits, but most of the time you will be addressing them either as a preventive measure or to address the problem you are already experiencing.

We have put together a quick table below to show each product and why you would choose one over the other for specific problems.

This is a quick comparison table to reference if you aren't interested in reading the entire article, or if you want a concise problem-and-solution table.

Quick comparison table

| Product | Best Application | Temperature Rating Maximum | Buy |

|---|---|---|---|

| Exoracing Titanium Exhaust Wrap | Manifolds and downpipes | Up to 1350°C | View |

| Exoracing Reflective Gold Tape | Intake pipes and bonnets | Up to 1100°C | View |

| Exoracing Turbo Blanket V3 | Turbo exhaust housings | Up to 1200°C | View |

| Exoracing Silicone heat sleeve | Hoses and wiring | Up to 1200°C | View |

| Exoracing Sewn heat sleeve | Hoses and wiring | Up to 600°C | View |

| Exoracing velcro heat sleeve | Hoses and wiring | Up to 250°C | View |

FAQ

Will a turbo blanket damage my turbocharger?

No, if fitted correctly using quality materials and proper fixings. The turbo blanket itself will never cause damage, but improper oiling or basic turbocharger maintenance will. It is always worth inspecting the core and exhaust housing to ensure there are no issues with the seals or gaskets.

Should I wrap my entire exhaust?

You typically get the most significant benefit from wrapping the manifold and the first section of the downpipe. We wouldn't recommend wrapping all the way to the exhaust tip (unless it's very short, such as out of the bonnet), as it will only trap moisture.

If the exhaust wrap is metres from the cylinder's heat source, the further back it is, the colder it will become. Without being able to burn off water, for example, it could cause rust or surface issues. You only need to wrap the parts that need it.

Where should I use reflective tape first?

Start near the hottest radiant heat sources, then protect nearby wiring and hoses. We would always go straight to the intake or intercooler piping, as this has the most significant effect on reducing radiant heat. The colder the air entering the engine, the better. The more heat we can keep away from the intake, the happier the engine will be!

Do I need all the products mentioned?

No. Start with the product that best matches your heat problem. Although the combined effects of everything in the article are significant, we always recommend using the specific product to address your issue at this time.

If you are planning a build from the start as a race car, for example, heat management is critical, as it will generate far more heat than a road car.

If you want a safe daily driver, you can get away with less heat management, though it is still crucial for component longevity. It is all about ensuring the car and engine are always performing at their best, and heat is your enemy for performance and reliability.

Conclusion

Engine bay heat does not have to be complicated. Match the problem to the right solution, start with the hottest areas, and build protection where it matters most.

Hopefully, you now have a much better understanding of the problems heat can cause in your car, and you are equipped to identify and resolve them quickly.

I've tried to cover the most common heat management issues, but if you have another issue not addressed here, please get in touch with us, and we can help resolve it.

Who knows, it might even become our next article and help someone else!

If you are interested in any of the products we discussed in this article, please click the link below. Your support helps us continue writing articles like this and produces video versions as well.

Shop the Exoracing Heat Management Range

We aim to educate as many people as possible about heat issues, and to reach the broadest possible audience, so thank you for reading!

About the author

I'm Matt, the owner of Exoracing Ltd, a UK-based performance parts brand specialising in automotive heat management and performance parts.

Since 2018, we've helped thousands of car enthusiasts and workshops reduce engine bay temperatures with tested, proven products, backed by firsthand experience from our own builds and those of our customers.

Got questions about your setup? Click the contact button at the top; we love hearing about your builds and helping where we can.